TM 5-3805-255-14

0013

Table 1. Preventive Maintenance Checks and Services (PMCS) for H100C - Continued.

.

LOCATION

ITEM TO

NOT FULLY MISSION

CHECK/

SERVICE

ITEM NO. INTERVAL

CAPABLE IF:

PROCEDURE

Weekly

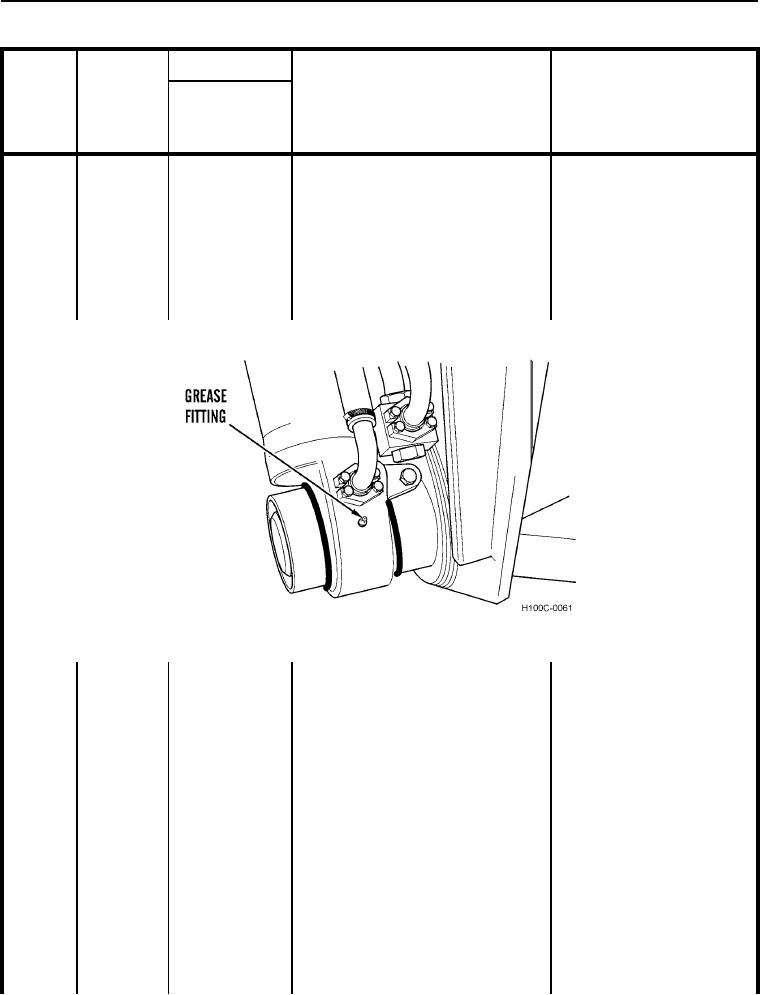

Boom Cylinder

a. Wipe grease fittings clean with a

27

Lubrication

rag.

b. Apply GAA grease to fittings (two

fittings at each pivot point). Wipe off

excess grease from fittings.

c. Inspect hydraulic hoses for

Cracks, splits, bulges, or soft

spots are evident in hoses, or

damage or leaks.

Class III leaks are evident.

Figure 17. Boom Cylinder Bottom Lubrication Point.

0013

0013-22