Fuel, Oil and Coolant Specifications

de-scaler should be used in accordance with the

manufacturer's recommendation for this purpose.

Soluble Oil

Soluble oil has been used as a corrosion inhibitor for

many years. It has, however, required very close

attention relative to the concentration level due to

adverse effects on heat transfer if the concentration

exceeds 1% by volume. For example: 1-1/4% of

soluble oil in the cooling system increases fire deck

temperatures 6% and a 2-1/2% concentration raises

fire deck temperature up to 15%. Soluble oil is not

recommended as a corrosion inhibitor.

Non- Chromates

Non-chromate inhibitors (borates, nitrates, nitrites,

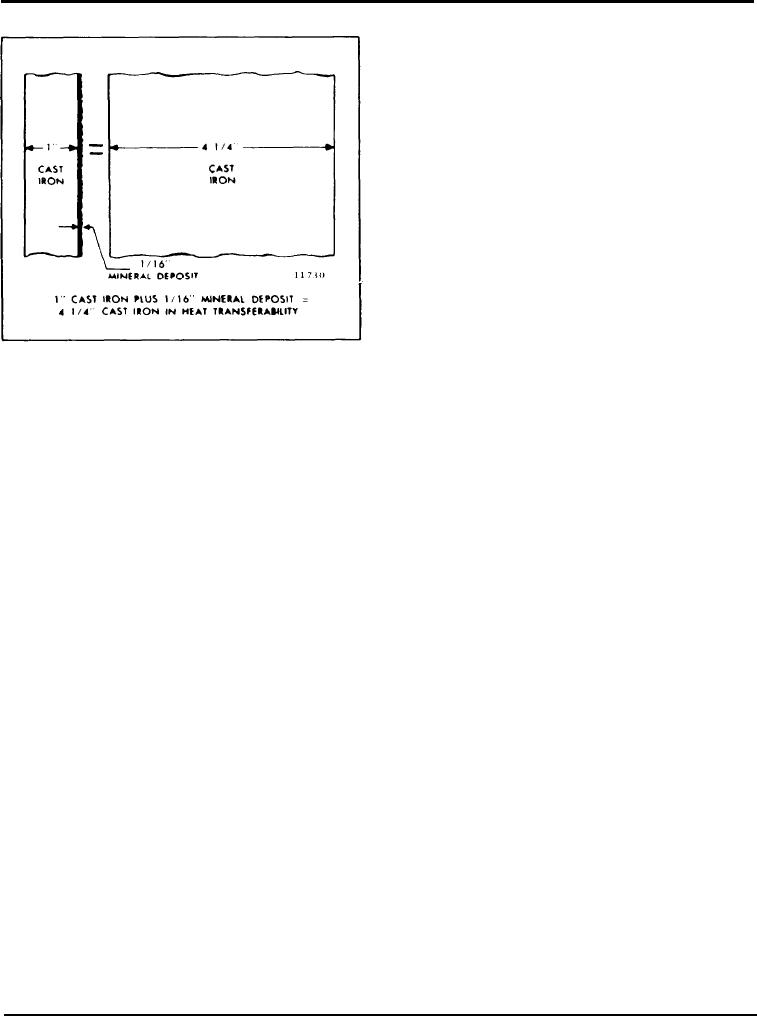

Fig. 2 - Heat Transfer Capacity

etc.) provide corrosion protection in the cooling system

with the basic advantage that they can be used with

compound which protects the metallic surfaces of the

either water or a water and permanent type antifreeze

cooling system against corrosive attack. Some of the

solution.

more commonly used corrosion inhibitors are chro-

mates, borates, nitrates, nitrites and soluble oil.

Depletion of all types of inhibitors occur through

INHIBITOR SYSTEMS

normal operation. Therefore, strength levels must be

maintained by the addition of inhibitors at prescribed

intervals. Always follow the supplier's recommenda-

An inhibitor system (Fig. 3) is a combination of

tions on inhibitor usage and handling.

chemical compounds which provide corrosion protec-

tion, pH control and water softening ability. Corrosion

NOTE: Methoxy propanol base permanent

protection has been discussed under the heading

antifreeze (such as Dowtherm 209, or equiva-

C o r r o s i o n Inhibitors. The pH control is used to

lent) must be re-inhibited only with compatible

maintain an acid free solution. The water softening

corrosion inhibitor systems.

ability deters formation of mineral deposits. Inhibitor

systems are available in various forms such as coolant

filter elements, liquid and dry bulk inhibitor additives,

and as an integral part of permanent antifreeze.

Chromates

Sodium chromate and potassium dichromate are two

of the best and most commonly used wafer system

Coolant Filter Elements

corrosion inhibitors. However, the restrictive use of

these materials, due to ecology considerations, has de-

Replaceable elements a r e available with various

emphasized their use in favor of non-chromates. Care

c h e m i c a l inhibitor systems. Compatibility of the

should be exercised in handling these materials due to

element with other ingredients of the coolant solution

their toxic nature.

cannot always be taken for granted.

Chromate inhibitors should not be used in permanent

Problems have developed from the use of the

magnesium l o w e r s u p p o r t p l a t e u s e d b y s o m e

t y p e antifreeze solutions. Chromium hydroxide,

manufacturer's in their coolant filters. The magnesium

commonly called "green slime", can result from the

u s e of chromate inhibitors with permanent type

plate will be attacked by solutions which will not be

antifreeze. This material deposits on the cooling

detrimental to other metals in the cooling system. The

system passages, r e d u c i n g the heat transfer rate

dissolved magnesium will be deposited in the hottest

zones of the engine where heat transfer is most

(Fig. 2), and results in engine overheating. Engines

which have operated with a chromate-inhibited water

critical. The use of an aluminum or zinc support plate

i n preference to magnesium is recommended to

must be chemically cleaned before the addition of

eliminate the potential of this type of deposit.

permanent type antifreeze. A commercial heavy duty

Page 82