TM 5-3805-257-14&P

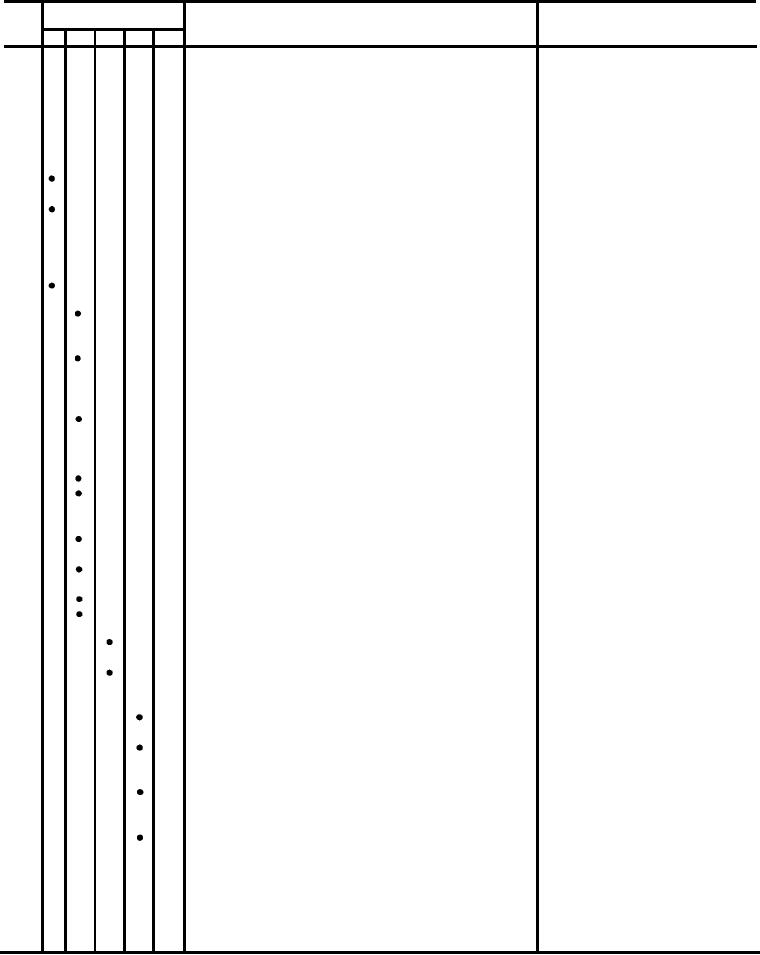

Table K-1. Operator/Crew Preventive Maintenance Checks and Services

A-After

W-Weekly

B-Before

D-During

M-Monthly

ITEM TO BE INSPECTED

Interval

Item

Equipment is not ready/

Procedure Check for and have repaired,

A

B

D

W

available if

filed. or adjusted as needed

M

No.

NOTE

PERFORM WEEKLY AS WELL AS BEFORE PMCS'S

IF:

a. You are the assigned operator but have not operated

vehicle since the last weekly.

b. You are operating the vehicle for the first time.

MAKE THE FOLLOWING WALK AROUND CHECKS:

1.

(Exterior of vehicle)

Class III leakage is evident. No fuel leak is

a. Check for evidence of leakage (oil, fuel, hydraulic fluid, or

coolant) on or under the scoop loader.

allowed.

Cracked welds, buckled or split seam and

b. Check roll over protective structure (ROPS) for obvious

loose or missing mounting bolts.

damage or loose mounting.

Tires have cuts or abrasions which would

c. Check tires for obvious damage or low pressure (correct pres-

result in tire failure during operation. One

sure is 45 psi).

or more tires missing or unserviceable.

2.

ENGINE

Check oil level at dipstick Add as required to FULL mark.

AIR CLEANER

3

Check indicator during operation. Clean or replace element when

red Bag completely fills indicator window

4.

TRANSMISSION and TORQUE CONVERTER

Check fluid level at dipstick. With engine running at operating

temperature, transmission in neutral level should be between "L"

and "H". Add as required.

5.

LIGHTS

Check lights for proper operation

INSTRUMENTS

6.

Gages not within ranges specified

Check for normal readings as follows:

22 to 28 volts

a. VOLTMETER

b. OIL PRESSURE

Low Idle (min)

.12 psi

.45 psi

Gov RPM.

165 to 185 F

GAGE

d. TORQUE CONVERTER

Max 250 F or Red Area

TEMPERATURE GAGE

.95 to 110 psi

e. AIR PRESSURE GAGE..

7.

Controls are not operable

CONTROL LEVERS AND PEDALS

Check for proper operation.

8.

AIR TANKS

Open drain cock IO release accumulated moisture Close cock.

9.

HYDRAULIC RESERVOIR

Check oil level with engine shutdown and bucket on ground.

Level should be at FULL mark. Refill as necessary

RADIATOR

10.

Check coolant level. Fill to the overflow.

BELTS

11.

Belt missing or broken

Inspect fan, alternator and air compressor or V-belts for frayed

condition or deterioration.

ALCOHOL EVAPORATOR (FREEZING TEMPERATURES

12.

ONLY)

Check and refill as required.

BATTERIES

13.

WARNING

Do not smoke or allow open flame in vicinity while

checking or filling battery. The battery generates hy-

drogen, a highly explosive gas.

Check level of electrolyte. If low, fill with clean water (distilled if

possible) to the split ring In freezing weather run engine at least 15

minutes to allow added water to mix with electrolyte.

K-2