TM 5-3805-291-10

OPERATION UNDER USUAL CONDITIONS - CONTINUED

0005 00

OPERATING WORK TOOLS - CONTINUED

0005 00

g.

To provide simultaneous control of machine hydraulics while changing direction of travel, use remote F/N/R

switch on loader control joystick to operate transmission.

h.

Approach pile of material to be loaded and fully lower bucket to correct dig height.

i.

Drive straight into pile, with bucket fully lowered at correct dig height. Enter pile of material at the toe.

j.

When more power is required, press and hold downshift switch on loader control joystick. This will cause trans-

mission to downshift automatically.

k.

Go as far as possible into pile, with bucket fully lowered, until loader meets increased resistance as bucket is fill-

ing.

N OT E

Raising bucket while driving into pile improves traction by transferring weight to loader front tires.

l.

Begin to raise bucket and continue to drive into pile.

m.

While still driving into pile, begin to tilt load backward while continuing to raise load.

n.

When load is fully tilted ("racked"), move transmission into R (REVERSE) and back away from pile. Transmis-

sion will be in 2nd gear.

Spreading a Load with GP Bucket. Dump load while moving machine slowly forward or in reverse, as needed.

5.

6.

Operating Rotary Sweeper.

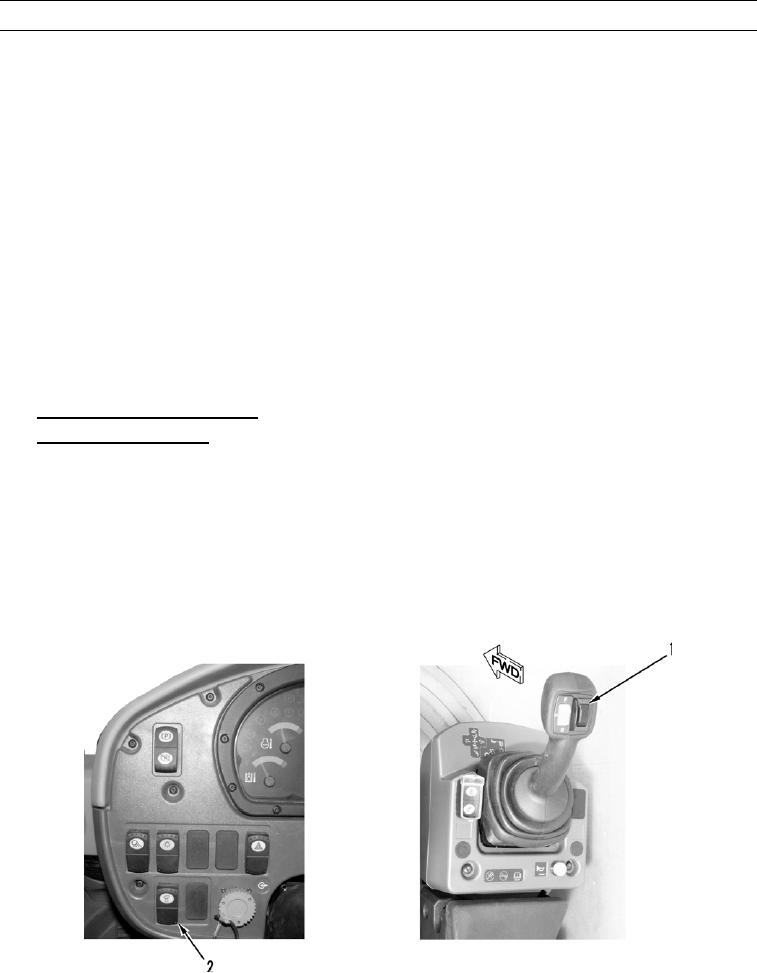

The continuous flow control switch supplies continuous flow of hydraulic fluid to the auxiliary hydraulic circuit (for

rotary sweeper operations) without continuously holding the auxiliary hydraulic control (thumb wheel [1]).

a.

Move thumb wheel (1) for the auxiliary control to the desired flow rate.

b.

Press and hold the continuous flow switch (2).

c.

Release the thumb wheel (1) after you release the continuous flow switch (2). The continuous flow function will

not be activated if the operator does not release the thumb wheel within 1 second of releasing the continuous flow

switch.

d.

Move the thumb wheel (1) or the continuous flow switch (2) in order to stop the flow to the auxiliary hydraulic cir-

cuit.

427-C0475

0005 00-16