TM 5-3805-291-10

OPERATION UNDER UNUSUAL CONDITIONS - CONTINUED

0006 00

PARKING BRAKE MANUAL RELEASE

0006 00

1.

The machine is equipped with spring-applied, oil-pressure-released parking brakes.

2.

If engine or brake oil system is not operating, parking brake is applied and machine will not move.

3.

Perform the following steps to manually release parking brake:

WAR N I N G

Ensure wheels are blocked before manually releasing parking brake. Failure to follow this warning may

result in machine rolling, causing injury or death to personnel or damage to equipment.

a.

Block wheels of disabled machine.

WARN I N G

Connect steering frame lock between front and rear frames before lifting, transporting, or servicing

machine in frame articulation area. Disconnect steering frame lock and secure in stowed position before

resuming operation. DO NOT operate machine with steering frame lock connected. Failure to follow this

warning may result in injury or death to personnel or damage to equipment.

b.

Connect steering frame lock (WP 0015 00).

c.

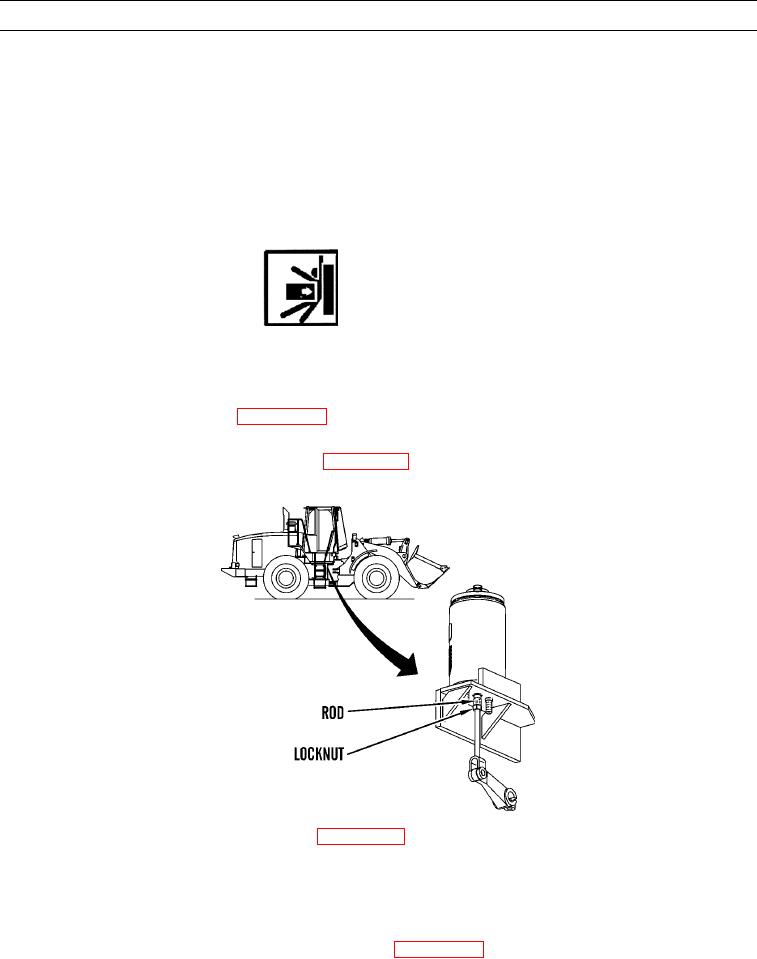

Locate parking brake actuator mounted in middle of front frame above front drive shaft.

d.

Use an adjustable wrench (Item 13, Table 2, WP 0026 00) to loosen locknut by 3/4 in. (19 mm).

e.

Turn rod until rod moves out of actuator enough to totally release parking brake.

427-C2056

f.

Disconnect and stow steering frame lock (WP 0015 00), then move disabled machine as needed.

CAU T I ON

Ensure parking brake is serviced and adjusted by Unit Maintenance before resuming machine operation.

Failure to do so could damage parking brake components or prevent parking brake from functioning

properly.

g.

When parking machine, connect steering frame lock (WP 0015 00), then fully tighten locknut on rod to engage

parking brake.

0006 00-6