TM 5-3805-291-23-2

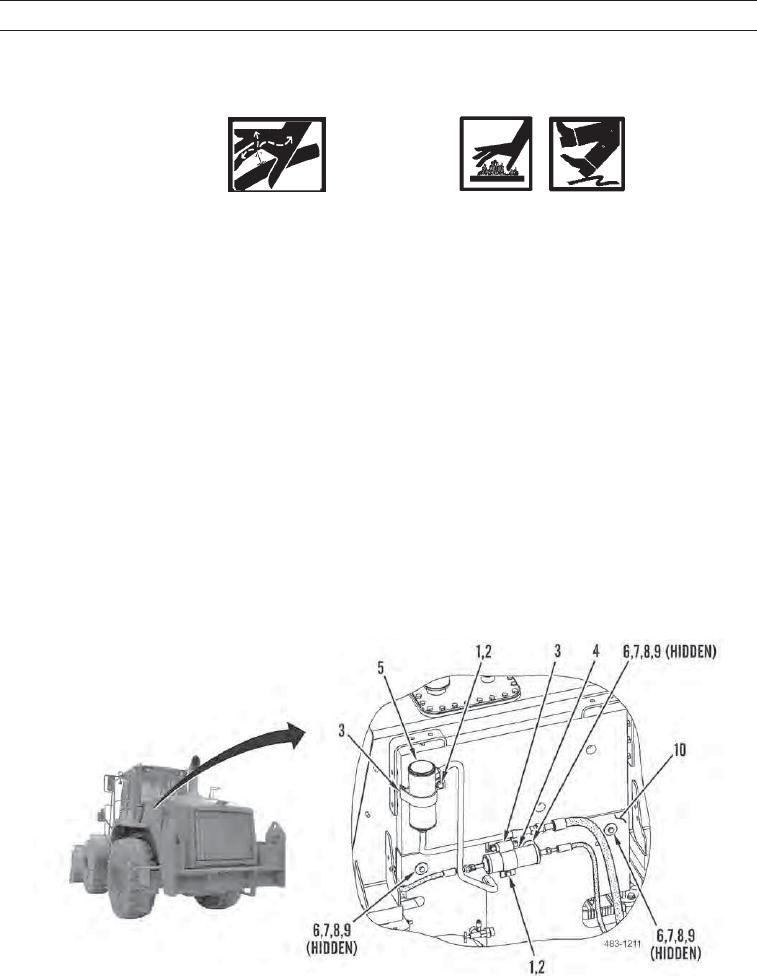

HYDRAULIC TANK REPLACEMENT - CONTINUED

0159 00

REMOVAL

1.

Remove two bolts (1) and washers (2) from clamps (3) and remove clamps from machine.

WARN I N G

DO NOT disconnect or remove any hydraulic system line or fitting unless engine is shut down and

hydraulic system pressure has been relieved. Tighten all connections before applying pressure. Escap-

ing hydraulic fluid under pressure can penetrate the skin, causing injury to personnel.

At operating temperature, hydraulic oil is hot. Allow hydraulic oil to cool before disconnecting any

hydraulic lines. Failure to follow this warning may result in injury to personnel.

Hydraulic oil used in the performance of maintenance can be very slippery. Immediately wipe up any

spills. Failure to follow this warning may result in injury to personnel.

C AU T I O N

Wipe area clean around all connections to be opened during removal. Cap lines and hoses and plug

openings after removing lines. Contamination of system could result in premature failure.

N OT E

Tag hoses and tubes prior to removal to ensure correct installation.

Use a container to catch any fluid that may drain from hoses or system. Dispose of fluid IAW local pol-

icy and ordinances. Ensure all spills are cleaned up.

2.

Position refrigerant dryer (4) and AC accumulator (5) aside.

3.

Remove three bolts (6), six washers (7), and two clips (8) and position cold start injector lines (9) aside.

4.

Remove sound suppression panel (10) from machine.

0159 00-2