TM 5-3805-291-23-2

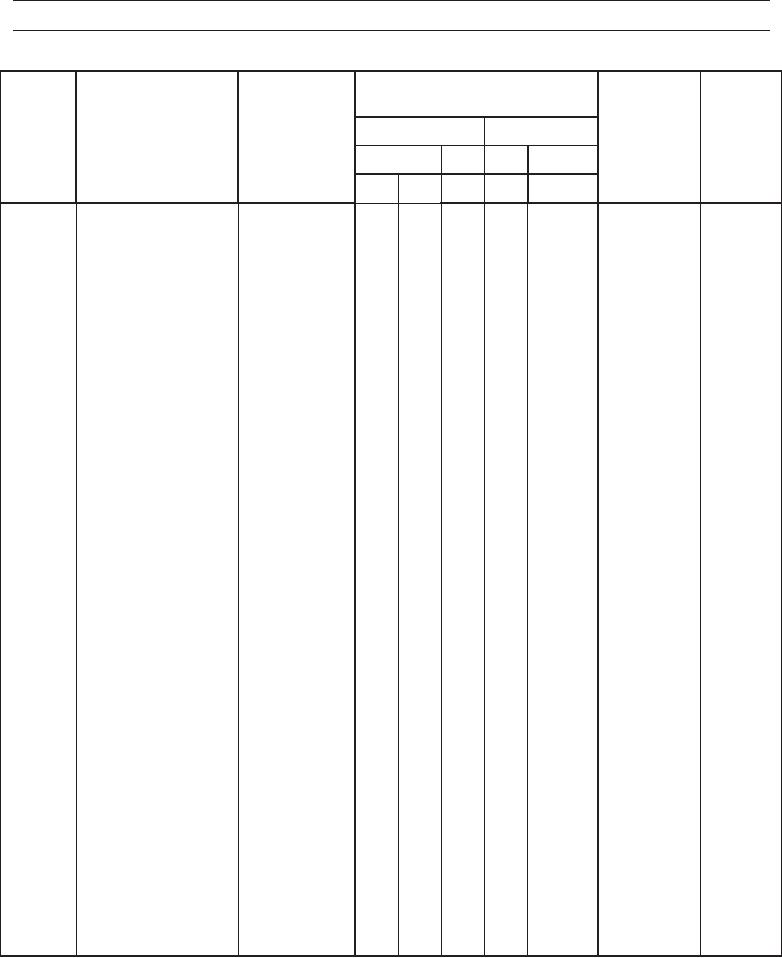

MAINTENANCE ALLOCATION CHART (MAC) - CONTINUED

0232 00

Table 1. Maintenance Allocation Chart (MAC) for 966H Loader - Continued.

(1)

(2)

(3)

(4)

(5)

(6)

MAINTENANCE LEVEL

FIELD

SUSTAINMENT

TOOLS AND

UNIT

DS

GS

DEPOT

GROUP

COMPONENT/

MAINTENANCE

EQUIPMENT REMARKS

C

O

F

H

D

NUMBER

ASSEMBLY

FUNCTION

REF CODE

CODE

06

ELECTRICAL

SYSTEM - Continued

Brake Pedal Position

Replace

0.5

90

Sensor

Engine Speed/Timing

Replace

0.5

70,90,98

Sensors

Fuel Level Sending Unit Replace

1.0

70,90

Hydraulic Oil

Replace

3.5

90

Temperature Sensor

Kickout and Position

Adjust

0.3

Sensors

Replace

1.0

90

Pressure Sensor/

Replace

0.5

70,90,98

Switches

Temperature Sensors/

Replace

0.5

70,90,98

Switches

Throttle Position Sensor Replace

0.5

70,90

Transmission Oil Filter Replace

0.5

90

Bypass Switch

Transmission Sensors

Adjust

0.5

70,90

Replace

0.5

70,90

0611

Horns and Alarms

Backup Alarm

Inspect

0.02

B

Replace

0.3

90

Electric Horn

Inspect

0.02

B

Replace

0.3

90

Quick Coupler Alarm

Replace

0.5

98

0612

Batteries and Storage

Batteries

Inspect

0.2

0.2

B

Service

0.2

90

B

Test

0.5

90

F

Replace

1.2

90

Battery Box

Replace

0.5

70,90

Battery Cables

Inspect

0.2

B

Replace

2.0

90

Battery Disconnect

Replace

0.5

90

Switch

0232 00-7