TM 5-3805-291-23-2

TORQUE LIMITS - CONTINUED

0234 00

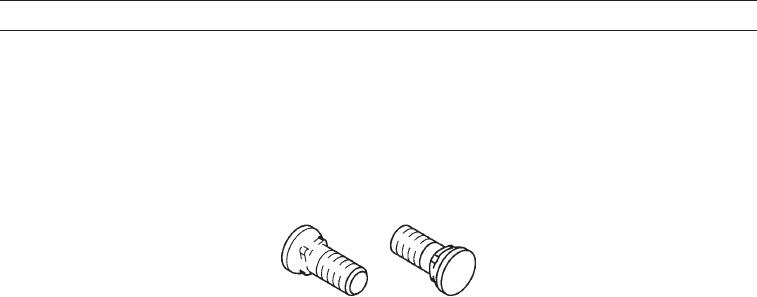

PLOW BOLTS

WAR N I N G

Personal injury can result when installing plow bolts. Appropriate safety equipment must be worn when

striking plow bolts. To avoid injury to your eyes and ears, wear protective glasses, and hearing protection

during this procedure.

427-C2066

1.

Clean all surfaces that had contact with bolt. Remove all occurrences of the following conditions: rust, paint, nicks, and

burrs.

2.

Tighten nut to correct torque. Refer to (Table 7).

3.

Use hammer to bolt head. Bolt head must be struck with significant force.

N OT E

Bolt head may be recessed below mounting surface. Use suitable punch to transfer hammer blow to bolt

head.

4.

Tighten nut to correct torque. Refer to (Table 7).

INSTALLATION OF FITTINGS

N OT E

Tightening sequence of the fasteners that attach tube assembly or hose assembly to the machine is very crit-

ical to proper function of machine. Sealing surfaces of tube assembly or hose assembly should be secured

squarely. Sealing surfaces of the tube assembly or hose assembly should be tightened to the serviced compo-

nent (control valve, cylinder, hydraulic motor, etc.). Perform this procedure prior to final tightening of any

clamps or slips that are used to fasten the tube assembly or hose assembly to machine.

Fittings have different connections. Fittings may have two completely different ends. Use proper torque for end of fit-

ting. The following list contains some common types of fittings:

Straight Thread O-Ring (STOR)

Adjustable Straight Thread O-Ring (STOR)

O-Ring Face Seal (ORFS)

Tapered Pipe Thread (NPT and NPTF)

37 Degree Flare Fitting

45 Degree Flare Fitting

45 Degree Inverted Flare Fitting

Split Flange Coupling

0234 00-6