TM 5-3805-298-23-2

0169

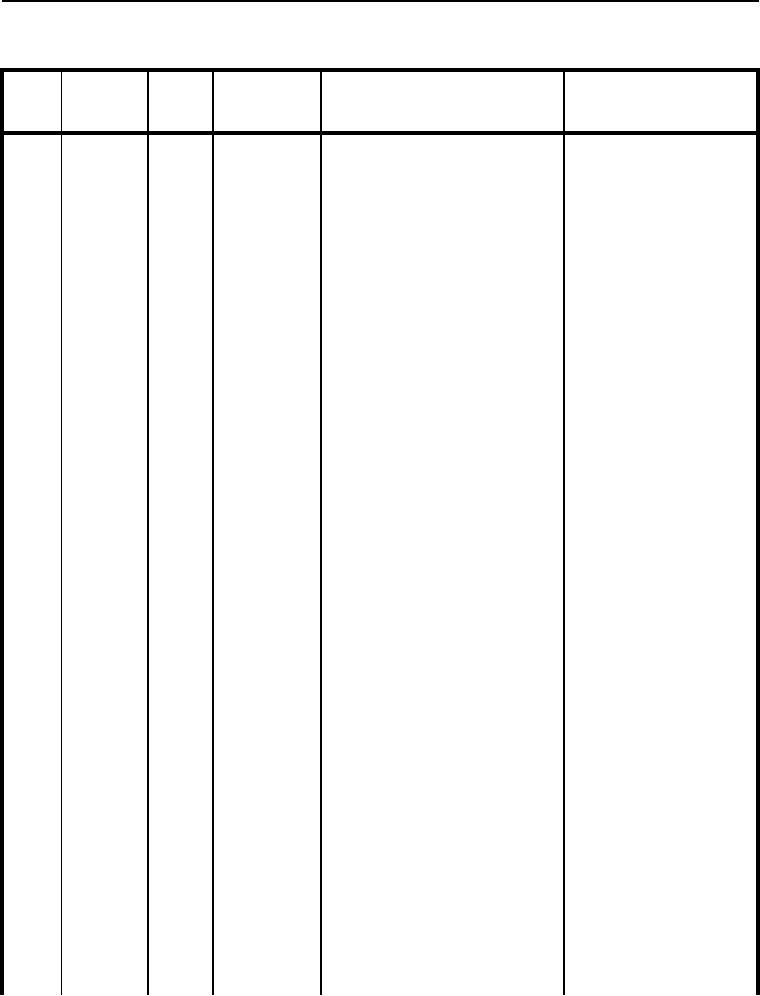

Table 1. Preventive Maintenance Checks and Services (PMCS) Including Lubrication Instructions -

Continued.

ITEM TO

CHECK/

EQUIPMENT NOT READY/

ITEM

MAN-

SERVICE

PROCEDURE

AVAILABLE IF:

NO.

INTERVAL HOURS

2

Every 250

Steering

Check steering column play:

Hours or

Column Play

a. Hold steering wheel with both

Quarterly

hands.

b. Try to move steering wheel from

one side to other side. Maximum

allowable movement in column

should not exceed 1 in. (25 mm).

1. Inspect pivot joint for loose

bolts and excessive wear.

2. Tighten bolts, if loose.

3. Replace column, if

Movement exceeds 1 in.

excessive wear (WP 0331).

(25 mm).

3

Every 500

Batteries and Inspect batteries and battery

Hours or

Battery Cables cables on each side of machine.

Quarterly

a. Ensure that batteries are

One or more batteries are

present. Inspect batteries for dirt,

missing or damaged.

corrosion, cracked cases, or other

damage.

b. Check for missing battery

One or more battery cables

cables. Inspect battery cables for

are missing or damaged.

looseness at battery posts, cracked

or broken insulation, signs of

broken wires, or signs of other

damage.

4

Every 500

Bucket Teeth

Check bucket teeth for loose pins,

Bucket teeth have holes.

Hours or

wear, damage, or holes.

Quarterly

a. If pins are loose, drive pins back

into tooth and bucket completely.

b. If teeth are damaged or contain

holes, replace bucket teeth

(WP 0423).

5

Every 500

Bucket Cutting Check bucket cutting edge wear

Hours or

Edge Wear

plates for damage or wear (TM 5-

Quarterly

Plates

3805-298-10). Distance between

center of mounting bolt holes and

edge of cutting edge must be 2.6

in.

(65 mm) or more.

a. If worn on one side, remove

wear plate, turn over, and reinstall

on bucket (WP 0424).

0169-3