TM 55-07/NAVSEA OP 3221 Rev 2

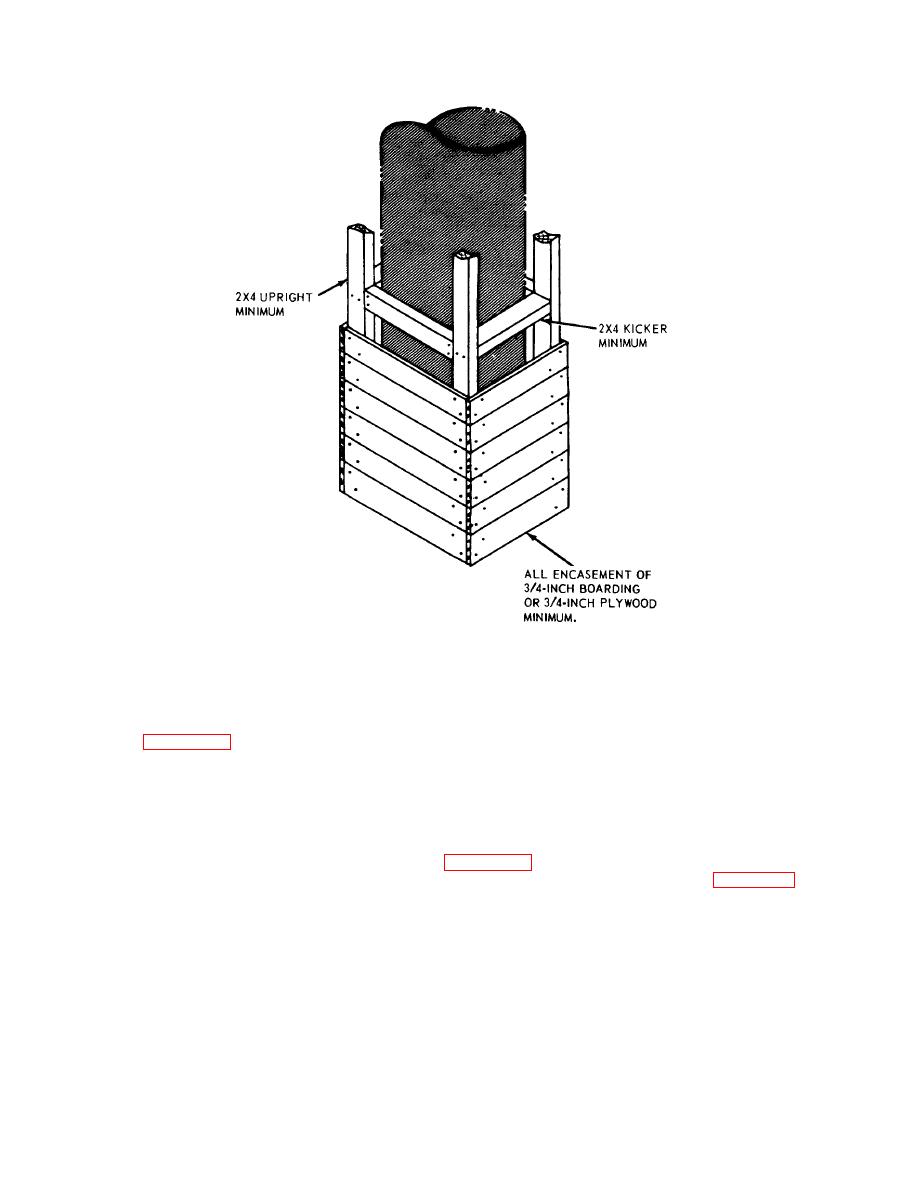

Figure 7-21 Complete encasement of kingpost within class 'A " magazine.

b. Partial Encasement. Provided the obstruction is not located within a class "A" magazine, partial encasement is

used to protect the cargo. Encasement procedures vary slightly, based on whether the sweatboard-to-sweatboard or

blockstowage method is employed.

(1) In the sweatboard-to-sweatboard method, obstructions such as ladders and stanchions are first encsed

a

as shown in figure 7-22. Unit loads are then stowed against the encased structure. Uprights are spaced around the

obstruction, and each upright should provide a bearing surface for the cargo. Kickers of similar size stock and spaced

not more than 36 inches apart are used to secure the uprights and unitize the structure. Partial encasement need not be

constructed higher than the adjacently stowed unit loads; however, the structure or ladder should remain accessible and

available for use, if necessary. If adjacent stowage of rectangular unit loads is intended, uprights and kickers should be

constructed of minimum 2by 4-inch stock. Overhanging unit loads are accommodated by boarding of minimum 2by 6-

inch lumber secured to the uprights at intervals compatible with the exposed surfaces of the cargo. Finally, the unit load

is stowed tightly so that it contacts the encased structure. Figure 7-23 shows a typical partial encasement of a stanchion

and ladder with a rectangular type of unit load. Also, partial encasement of an air vent is shown in figure 7-24.

7-26