TM 55-07/NAVSEA OP 3221 Rev 2

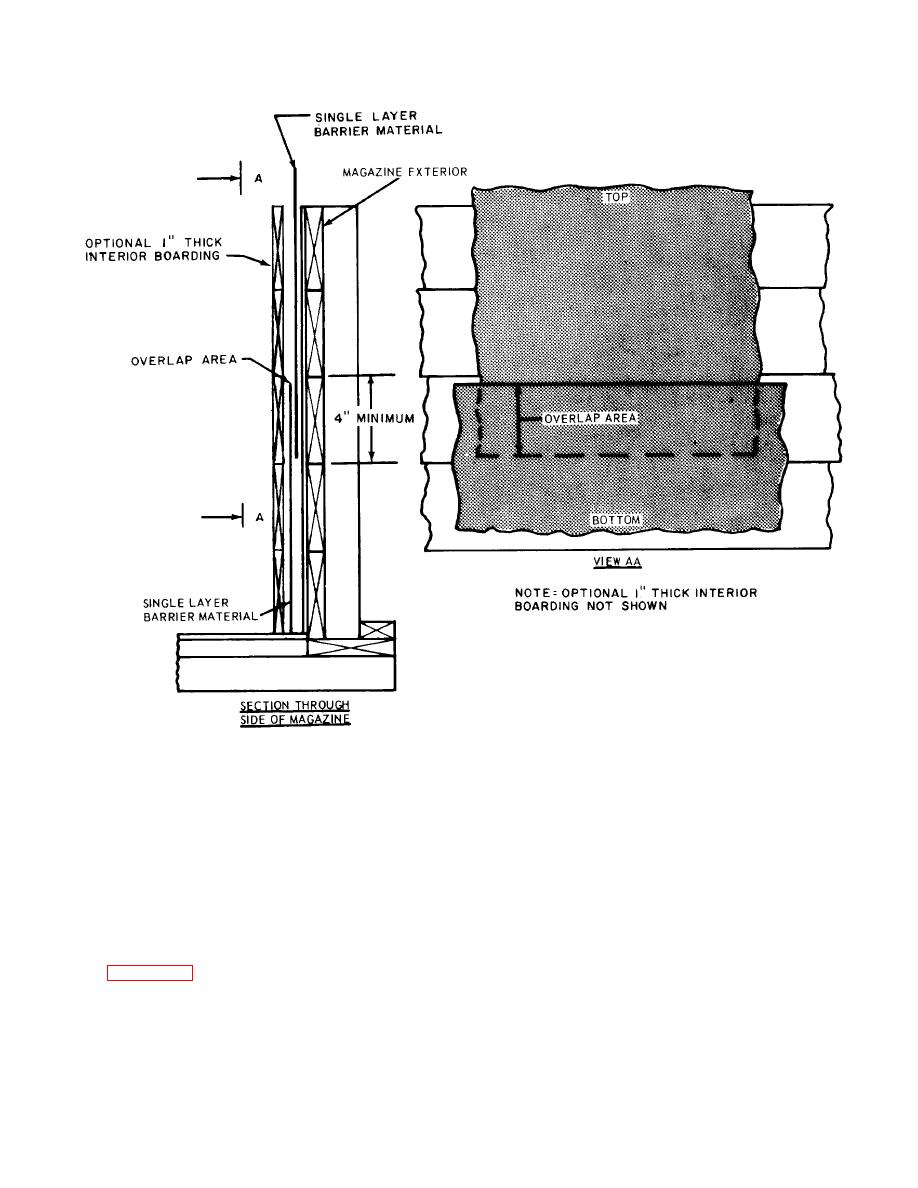

Figure 730. Installation of barrier material.

7-9. Tomming

The resultant motion initiated by the cyclic rising and falling action of a ship's bow and stern produces acceleration forces

in the vertical direction, which can be significant in securing considerations. In addition, these forces complement the

across-the-deck roll forces when the ship rolls away from the vertical. Vertical forces encountered in a marine shipment

are often of such low magnitude that securing to resist resultant cargo motion is unnecessary. Palletized and skidded

unit loads are not usually secured to resist vertical motion. flowever, light items, shock-sensitive items, and certain

loose, cylindrical items that are susceptible to "riding up" on each other in heavy seas require overhead securement

known as tomming. Tomming is accomplished by tying down the cargo to the ship's overhead structures. Overhead

bracing frequently uses the A-frame to provide vertical securement. Strips of lumber are laid on the stowed items and

serve as the foundation for the A-frames, thereby also providing a means for preventing the "riding up" of adjacent items.

a. Figure 7-31 illustrates the construction details for A-frame tomming. To prevent excessive flexing of the frame

members as the height of the structure increases, the required lumber must be similarly increased. In most cases, 2by 6-

inch stock will be used to construct the A-frame. When the height of the overhead exceeds 10 feet, the legs of the frame

shall be constructed of 4by 4-inch lumber. The angle of the frame (as measured between legs at the vertex) should not

exceed 45 Legs of' the A-frame that are greater than 3 feet in length

.

7-37