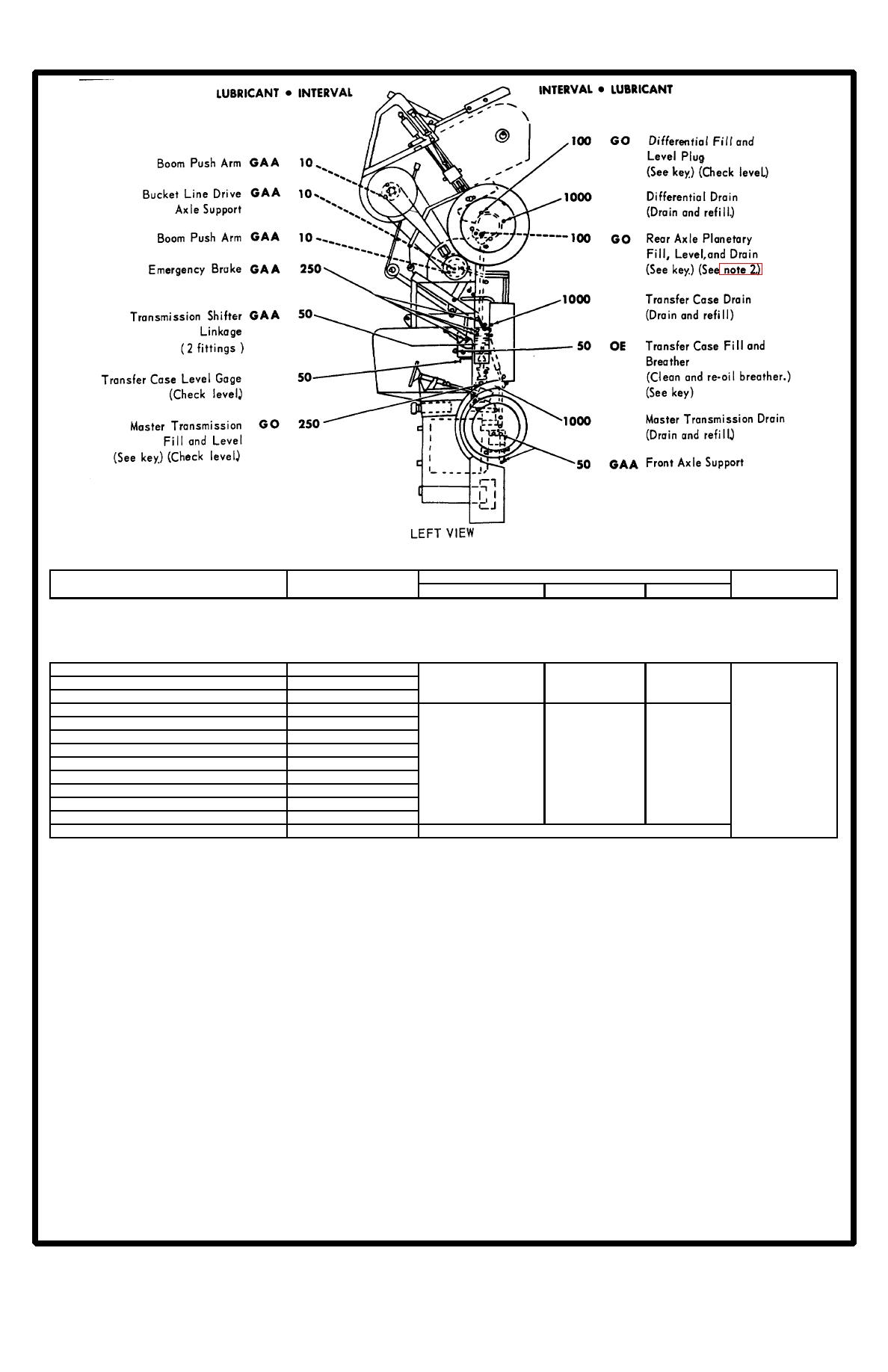

LO 5-3805-212-20-1

NOTE 2

note 2

-.KEY -

EXPECTED TEMPERATURES

LUBRICANTS

CAPACITY

INTERVALS

Above +32F

+ 40F to -10 F

0F to -65F

FOLD

FOLD

_____________

____________

OE -

OIL, Engine, Heavy Duty

Transfer Case

64 qt

OE 50

OE 30

OE 10

Oil Can Points

Intervals

GO -

LUBRICATING OIL, Gear

given are

Conveyor, Drive Gearcase

1/2 qt ea

in hours of

Master Transmission

14 qt

Conveyor Shift Gearbox

1/2 qt

GO 90

GO 90

GOS

normal

Differential

15 qt

operation.

Rear Axle Planetary

8 qt ea

GOS- LUBRICATING OIL, Gear, Sub-zero

GAA - GREASE, Automotive and Artillery

All Temperatures

NOTES:

3. OIL CAN POINTS. Every 50 hours lubricate all control linkage and

1.

FOR OPERATION OF EQUIPMENT IN PROTRACTED COLD

exposed adjusting threads with OE. Copy of this Lubrication Order will

remain with the equipment at all times; instructions contained herein are

TEMPERATURES BELOW -10F. Remove lubricants prescribed in the key

mandatory.

for temperatures above -10F. Clean parts with SOLVENT, dry-cleaning.

Relubricate with lubricants specified in the key for temperatures below -10F.

By Order of the Secretary of the Army:

G. H. DECKER,

2. REAR AXLE PLANETARY. Every 100 hours rotate wheel until plug is

General, United States Army,

horizontal with center line of axle. Remove plug, check level, and re-install.

Official:

Chief of Staff.

Every 1000 hours rotate wheel until plug is at bottom center, remove plug,

J. C. LAMBERT,

and drain. Rotate wheel back to level point, fill, and reinstall plug.

Major General, United States Army,

the Adjutant General.

GPO. 1970 431-065/164