TM 5-2420-231-23-1

0021

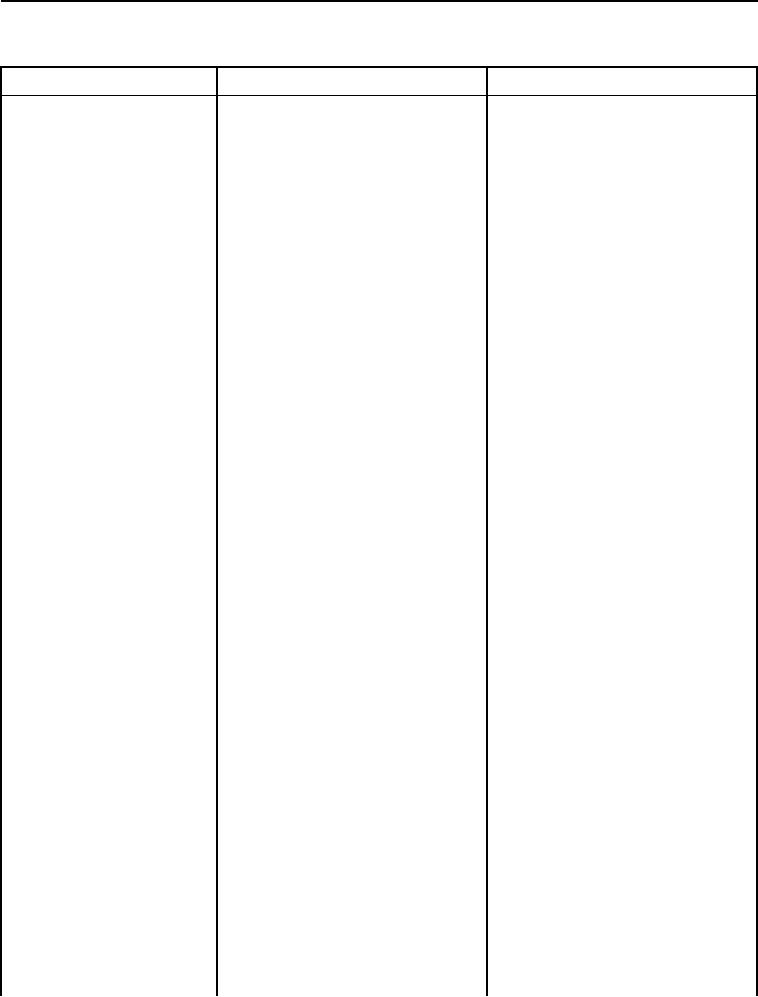

Table 1. Engine Coolant Temperature Gauge Indicates High Temperature,

Does Not Function, or Is Inaccurate - Continued.

021

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Engine Coolant Temperature Test Step 2. Inspect for Leaks in

Gauge Indicates High

Reservoir.

Temperature, Does Not

Reservoir OK - Proceed to step 2.

1. Add engine coolant to coolant res-

Function, or Is Inaccurate -

ervoir (Figure 2, Item 2) (WP 0090)

Reservoir Cracked, Damaged, or

Continued

Leaking - Replace reservoir (WP

and inspect reservoir for cracks,

0096).

damage, and Class III leaks.

2. Inspect radiator (Figure 2, Item 1)

Radiator OK - Proceed to step 3.

for damage and Class III leaks.

Radiator Leaking - Replace radiator

(WP 0092).

Proceed to Test Step 9.

Radiator Damaged - Replace radiator

(WP 0092).

Proceed to Test Step 9.

3. Inspect coolant recovery hose

Recovery Hose and Clamp OK -

(Figure 2, Item 5) for loose clamps

Proceed to Test Step 3.

(Figure 2, Items 3 and 7), cracks,

Recovery Hose Clamp Loose or

splits, damage, and Class III leaks

Leaking at Connection - Tighten or

at radiator connection (Figure 2,

replace coolant recovery hose clamps

Item 6) and reservoir connection

(WP 0097).

(Figure 2, Item 4).

Proceed to Test Step 9.

Recovery Hose Cracked, Split,

Damaged, or Leaking - Replace

coolant recovery hose (WP 0097).

Proceed to Test Step 9.

0021-4