TM 5-2420-231-23-1

0066

Table 1. Loader Clamshell Does Not Operate Correctly.

0066

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Loader Clamshell Does Not

Test Step 1. Test Operation of Loader

Operate Correctly

Systems.

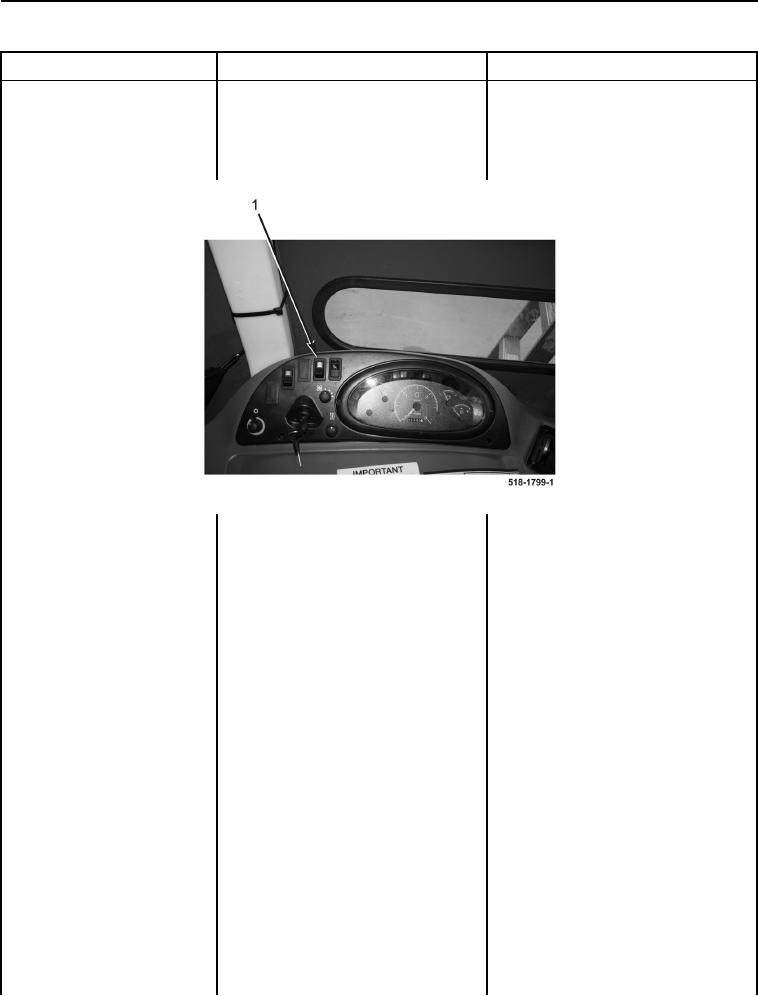

1. Ensure ride control switch (Figure

1, Item 1) is in off position (TM 5-

2420-231-10).

Figure 1. Ride Control Switch.

0066

2. Operate loader clamshell (TM 5-

Loader Clamshell Cylinders Operate

Slowly - Proceed to Test Step 2.

2420-231-10). Monitor and record

machine operation.

Loader Clamshell Will Not Operate -

Proceed to Test Step 4.

Test Step 2. Inspect Loader

Clamshell Cylinder Hydraulic Tubes

and Hoses.

1. Ensure hose connections are tight.

Start and run machine (TM 5-

2420-231-10).

2. Inspect left loader clamshell cylin-

Loader Clamshell Cylinder Hydraulic

der hydraulic hoses (Figure 2, Item

Hoses OK - Proceed to step 3.

8), and right loader clamshell cylin-

Loader Clamshell Cylinder Hydraulic

der hydraulic hoses (Figure 2, Item

Hoses, Leaking, Kinked or Damaged

2) (WP 0237) for kinks, damage,

- Replace loader clamshell cylinder

and Class III leaks between clam-

hydraulic hoses (WP 0237).

shell cylinders (Figure 2, Items 4

Proceed to Test Step 7.

and 7), and check valve (Figure 2,

Item 1).

3. Inspect loader clamshell cylinder

Loader Clamshell Cylinder Hydraulic

Hoses OK - Proceed to step 4.

hydraulic hoses (Figure 2, Item 3)

Loader Clamshell Cylinder Hydraulic

for kinks, damage, and Class III

Hoses Leaking, Kinked or Damaged

leaks between check valve (Figure

- Replace loader clamshell cylinder

2, Item 1), and quick-connect fit-

hydraulic hoses (WP 0237).

tings (Figure 2, Item 5).

Proceed to Test Step 7.