TM 5-3805-255-14

0003

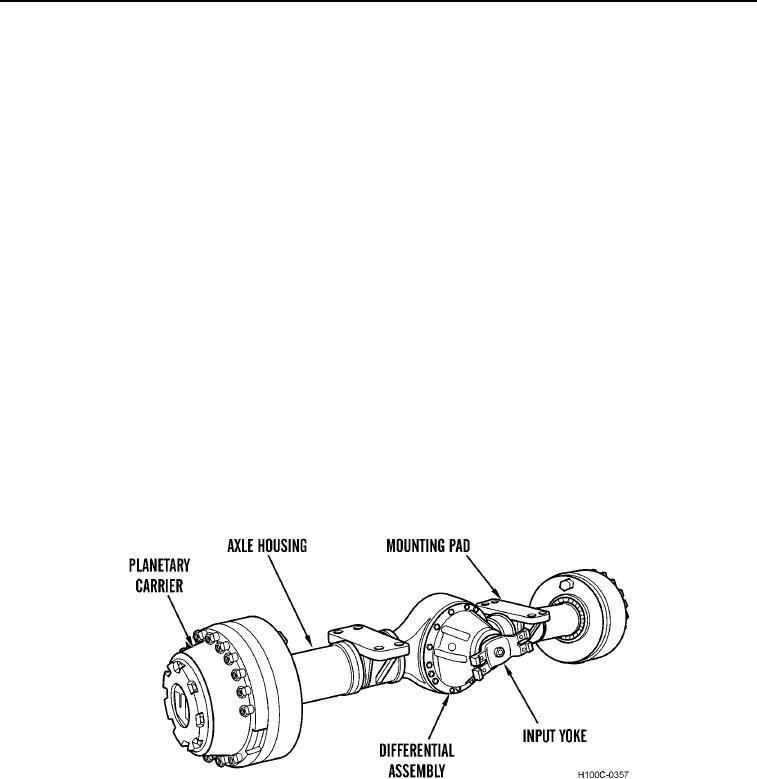

FRONT AND REAR AXLES

0003

1. The axle assemblies accomplish three main functions: transmit the out-going twisting force (torque) at 90 to

the left and right of its input direction, increase the input torque through reduction gearing, and provide a

means of securing the wheels and at the same time support the loader. To each of these main functions

several secondary requirements are added suggesting a complex piece of machinery. In reality, each axle uses

a minimum of parts to carry out its many functions. Simplicity of design increases reliability and provides easy

servicing.

2. Both axles are full floating, double reduction type. The axles are rigidly attached to their supporting members;

the front main frame in the case of the front axle and an oscillating cradle called a bolster for the rear. By

allowing the rear axle to oscillate, the loader is assured great stability in rough terrain.

3. The first gear reduction takes place in the differential; the second in the planetaries. Each wheel revolves on

two tapered roller bearings mounted on the axle spindle. The axles are full floating in that none of the weight is

supported by, or transmitted to, the axle shafts. All weight on the axle is supported by the wheels, bearings,

and axle housing.

4. The differential assemblies are rigidly mounted; one on the forward side of the rear axle housing and one on

the rear side of the front axle housing. The differentials are connected by splined yokes to the yokes on the

propeller shafts from the transmission.

5. The basic differential consists of a hypoid ring gear, pinion gear, and spider gear assembly. The differential and

spider gear assembly rotate on tapered roller bearings. The pinion is straddle mounted, having two tapered

roller bearings in front of the pinion teeth to take the forward and reverse thrust and a straight roller bearing

behind the pinion teeth to take the forward and reverse thrust and a straight roller bearing behind the pinion

teeth to carry the radial load.

6. Three functions of the differential are transmitting torque from the propeller shaft to the axle shafts, producing

the first torque multiplication in the double reduction axles, and allowing one drive wheel to rotate at a different

speed than the opposite wheel.

Figure 13. Typical Solid Axle.

03

0003-18