TM 5-3805-255-14

0095

VALVE RECONDITIONING CONTINUED

Refacing Valve Seats and Seat Inserts Continued

00095

CAUTION

Maximum amount of material which can be removed from valve seat is 0.010 in.

(0.25 mm) for exhaust and 0.012 in. (0.30 mm) for intake. However, if both valve face and

seat must be refinished, combined total matter removed from both must not exceed 0.015

in. (0.38 mm). Only minimum amount needed to make a good valve seat contact should

be removed. If necessary to remove more than maximums stated above, valve and/or

valve stated inserts must be replaced. Failure to follow caution may result in damage to

engine.

5. Check seat concentricity with valve guide by using a dial indicator mounted on pilot. Run indicator around seat

surfaces, thereby testing for concentricity. Runout must not exceed a total of 0.002 in. (0.05 mm).

6. Finish left by regular type grinding stone is usually satisfactory for practical purposes. Lapping valves into their

seats is unnecessary if precision equipment is used and extreme care taken. Use Prussian blue to test refaced

valves and seats roundness and concentricity. Spread an extremely thin film of this blue on valve face and

insert valve into its guide.

With pressure on exact center of valve head, make a quarter-turn rotation in seat. Remove valve and inspect

impression made upon seat by transfer of blueing, and upon valve face by removal of blueing. Check several

times to be sure that no error was made.

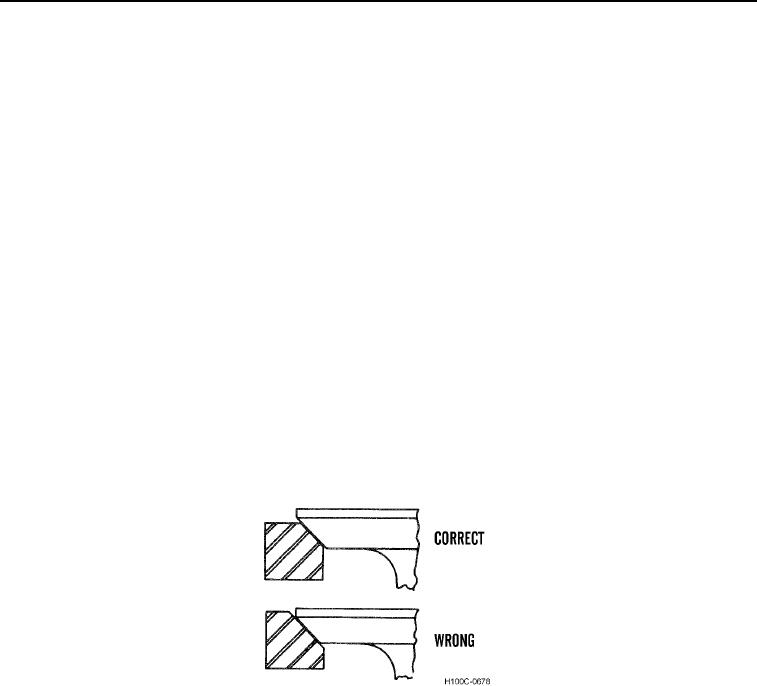

7. After grinding seats, it may be found that seats are considerably wider than width recommended in Table 3.

Valve seats that are too wide may be narrowed by grinding down top edge of seat with a stone mounted on

grinder head (Figure 20). Stone must be a smaller angle than valve seat (15 degrees preferably).

Figure 19. Valve Seat Width Must Conform to Specifications and Center of Valve Face.

0095

0095-18