Preventive Maintenance

Item 9

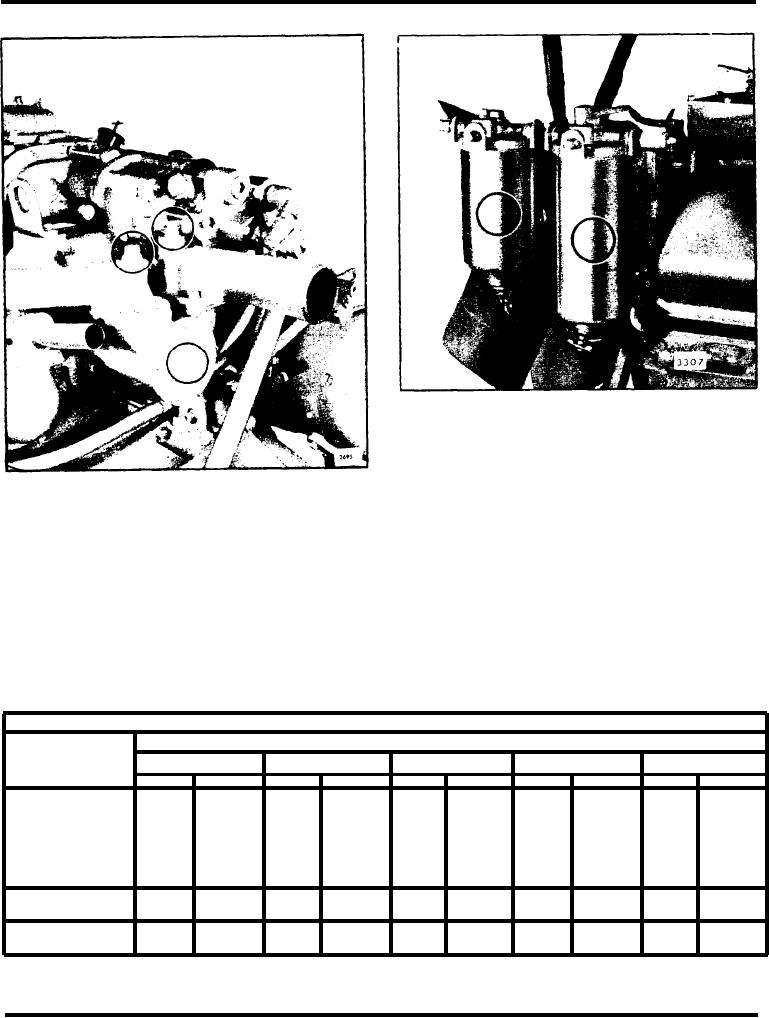

Open the drain at the bottom of the fuel tank every

500 hours or 15,000 miles (24 140 km) to drain off any

water or sediment.

Items 6 and 7

should not be operated with a dry pump. Prime the

Item 9

pump, if necessary, b y removing the pipe plug

provided in the pump inlet elbow and adding water.

Install new elements every 300 hours or 9,000 miles

Reinstall the plug.

(14 484 km) or when plugging is indicated.

A method of determining when elements are plugged

Item 8

to the extent that they should be changed is based on

the fuel pressure a t the cylinder head fuel inlet

Keep the fuel tank filled to reduce condensation to a

manifold and the inlet restriction at the fuel pump. In

minimum. Select the proper grade of fuel in

a clean system, the maximum pump inlet restriction

accordance with the Diesel Fuel Oil Specifications.

Fuel Pressure at Inlet Manifold

Speed (rpm)

Engine

2300

2100

1800

2000

1200

kPa

psi

kPa

kPa

kPa

psi

psi

psi

kPa

psi

V-71, V-71N

310-483

45-70

241-483

35-70

310-483

45-70

(6, 8, 12V) Normal

45-70

310-483

45-70

45-70

310-483

310-483

8V-71T Normal

45-60

310-414

310-414

45-60

12V-71T Normal

45-70

310-483

16V-71 Normal

35-70

241-483

45-70

310-483

35-70

241-483

45-70

310-483

45-70

310-483

16V-71N Normal

16V-71T Except

Standby Gen. Set

45-70

310-483

45-70

310-483

45-70

310-483

16V-71T With

50-70

345-483

Standby Gen. Set

TABLE 1

Page 65