Preventive Maintenance

will depress the belt 1/2" to 3/4" If belt tension gage

grease at the grease fittings. At temperatures above

BT-33-73FA or equivalent is available, adjust the belt

+30F (-1C), use a No. 2 grade grease. Use a

tension as outlined in Table 2.

No. 1 grade grease below this temperature. Lubricate

all other control mechanisms, as required, with engine

NOTE: When

installing or adjusting an acces-

oil.

sory drive belt,

be sure the bolt at the accessory

adjusting pivot

point is properly tightened, as

well as the bolt

in the adjusting slot.

Item 19

There is no scheduled interval for performing an

engine tune-up. As long as the engine performance is

Adjust Poly-V Fan Belt (16V-71)

satisfactory, a complete tune-up is not required. Minor

adjustments in t h e valve and injector operating

The fan belt should be neither too tight nor too loose.

mechanisms and governor should only be required

Carelessness in making a belt adjustment can be

periodically to compensate for normal wear on parts.

dangerous. Too tight a belt imposes an undue load on

the fan bearings and shortens the life of the belt. Too

loose a belt allows slippage and lowers the fan speed,

causes excessive belt wear and leads to overheating of

Item 20

the cooling system.

New standard V-belts will stretch after the first few

hours of operation. Run the engine for 15 seconds to

Before a Poly-V belt is installed, it is very important

seat the belts, then re-tension them. Retighten the fan

that the crankshaft pulley (10 grooves) and the fan

drive, pump drive, battery-charging alternator and

drive pulley (11 grooves) are in alignment. The extra

other accessory drive belts after 1/2 hour or 15 miles

groove in the fan drive pulley can be on the inside or

(24 km) and again after 8 hours or 240 miles (386 km)

the outside of the pulley, depending upon alignment

of operation. Thereafter, check the tension of the drive

requirements.

belts every 200 hours or 6,000 miles (9 656 km) and

adjust, if necessary. Too tight a belt is destructive to

Misalignment between the crankshaft pulley and the

the bearings of the driven part; a loose belt will slip.

fan drive pulley cannot be more than .009" per inch

o f center line distance. A straight line can be

Replace all belts in a set when one is worn. Single belts

determined by placing a straight edge on the rims of

of similar size should not be used as a substitute for a

the pulleys. A spacer is available to facilitate pulley

m a t c h e d belt set; premature belt wear can result

alignment, if necessary. The spacer mounts between

because of belt length variation. All belts in a matched

the crankshaft pulley and the vibration damper hub.

belt set are within .032" of their specified center

distances.

Poly-V belts require a special procedure for proper

belt tension.

Adjust the belt tension so that a firm push with the

thumb, at a point midway between the two pulleys,

1. After the belts have been initially adjusted, run the

engine under a light load for one-half hour.

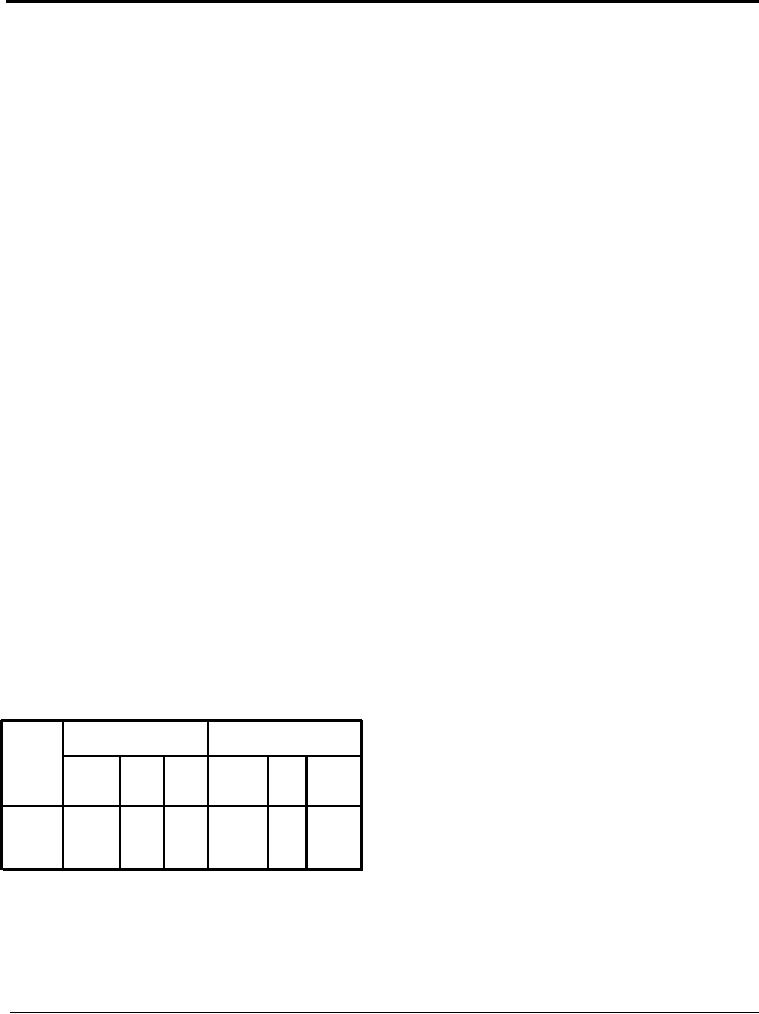

"V" and "POLY V" BELT TENSION TABLE (1 lbs-belt)

2. Stop the engine and check the belt tension with the

Alternator or

belt "hot"; use belt tension gage BT-33-86AE6-40A,

Fan Drive

Generator Drive

or equivalent, which has a range of 60 to 400 pounds.

One

Two 3/8"

8 Rib (K)

10 Rib (L)

2 or 3

Single

Poly V

Poly V

1/2"

or 1/2"

3. If the tension value is not between 280 and 360

Belt

Belts

Model

Belt

Belt

Belts

Belts

pounds, re-adjust the belt tension.

50-70

110-130

40-50

60-80

80-100

6, 8V-71

CAUTION: Because the allowable load the

50-70

12V-71

70-90

40-50

crankshaft bearing can carry is critical, do not

40-50

50-70

16V-71

310-360 90-120

exceed the maximum tension value of 360

pounds.

Belt tension is 50-70 far a single premium high capacity belt (.785"

wide) used to drive a 12 cfm air compressor.

4. Run the engine at full load for eight hours and then

Adjust all V-belts with belt tension gage BT-33-73 FA or equivalent.

recheck the belt tension.

Adjusr all Poly V-belts with belt tension gage *BT-33-AE6-40A

(Burroughs) or equivalent J23586 (Kent Moore) *Range 60-400 lbs

5. If the belt tension is too tight or too loose, keep the

gage in place and adjust the belt tension, to the

TABLE 2

prescribed value, a t t h e a c c e s s o r y m o u n t i n g o r

Page 69