Engine Tune-Up

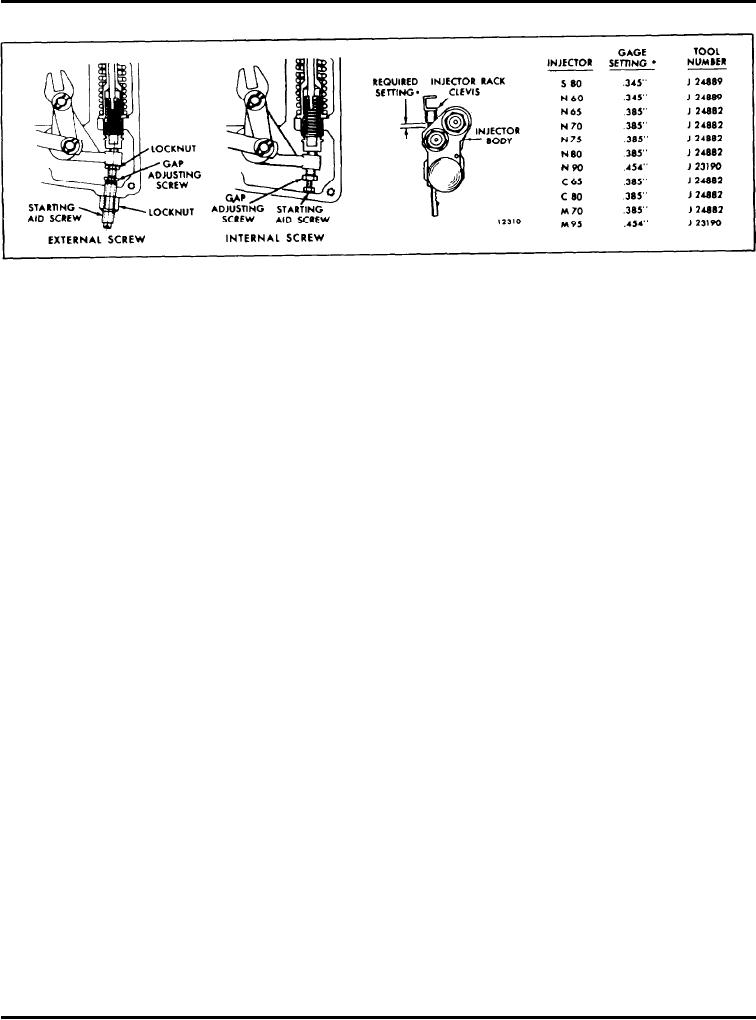

Fig. 6 - Starting Aid Screw Adjustment

IMPORTANT: The effectiveness of the starting

C A U T I O N : Once the No. IL and No. IR

aid screw will be eliminated if the speed control

injector rack control levers are adjusted, do not

lever is advanced to wide open throttle during

try to alter their settings. All adjustments are

starting.

made on the remaining control racks.

After the normal governor running gap of .0015" has

NOTE: Overtightening of the injector rack

been set and the injector racks positioned, adjust the

control lever adjusting screws during installa-

starting aid screw.

tion or adjustment can result in damage to the

injector control tube. The recommended torque

of the adjusting screws is 24-36 in-lb(3-4 Nm).

1 . On current turbocharged engines, adjust the

external starting aid screw as follows:

12. When all of the injector rack control levers are

adjusted, recheck their settings. With the control tube

a. With the engine stopped, place the governor stop

lever in the full-fuel position, check each control rack

lever in the run position and the speed control

as in Step 7. All of the control racks must have the

lever in the idle speed position.

same "spring" condition with the control tube lever in

the full-fuel position.

b. Adjust the starting a i d screw to obtain the

required setting between the shoulder on the

13. Insert the clevis pin in the fuel rod and the injector

injector rack clevis and the injector body (Fig. 6).

control tube levers.

Select the proper gage and measure the setting at

any convenient cylinder. When the starting aid

screw is properly adjusted, the gage should have a

14. Turn the idle speed adjusting screw in until it

small clearance of 1/64" (.397 mm) in the space

projects 3/16" from the lock nut, to permit starting

along the injector rack shaft between the rack

the engine.

clevis and the injector body.

15. Use new gaskets and replace the valve rocker

c. After completing the adjustment, hold the starting

covers.

aid screw and tighten the lock nut.

d. Check the injector rack clevis-to-body clearance

Adjust Starting Aid Screw - Turbocharged

after performing the following:

Engines

1. Position the stop lever in the run position.

The starting aid screw (Fig. 6) is threaded into the

governor housing of current engines and into the

2. Move the speed control lever from the idle

governor gap adjusting screw of early engines. This

speed position to the maximum speed position.

screw is adjusted to position the injector racks at less

than full fuel when the governor speed control lever is

3. Return the speed control lever to the idle speed

in the idle position. The reduced fuel makes starting

position.

easier and reduces the amount of smoke on start-up.

Page 95