Engine Tune-Up

temperature and with the buffer screw backed out to

avoid contact with the differential lever, turn the idle

speed adjusting screw until the engine is operating at

approximately 15 rpm below the recommended idle

speed (Fig. 9). The recommended idle speed is 400-

450 rpm, but may vary with special engine

applications.

IMPORTANT: It may be necessary to use the

buffer screw to eliminate engine roll. Back out

the buffer screw, after the idle speed is

established, to the previous setting (5/8").

2. Hold the idle screw and tighten the lock nut.

3. Install the high-speed spring retainer cover and

tighten the two bolts.

Adjust Buffer Screw

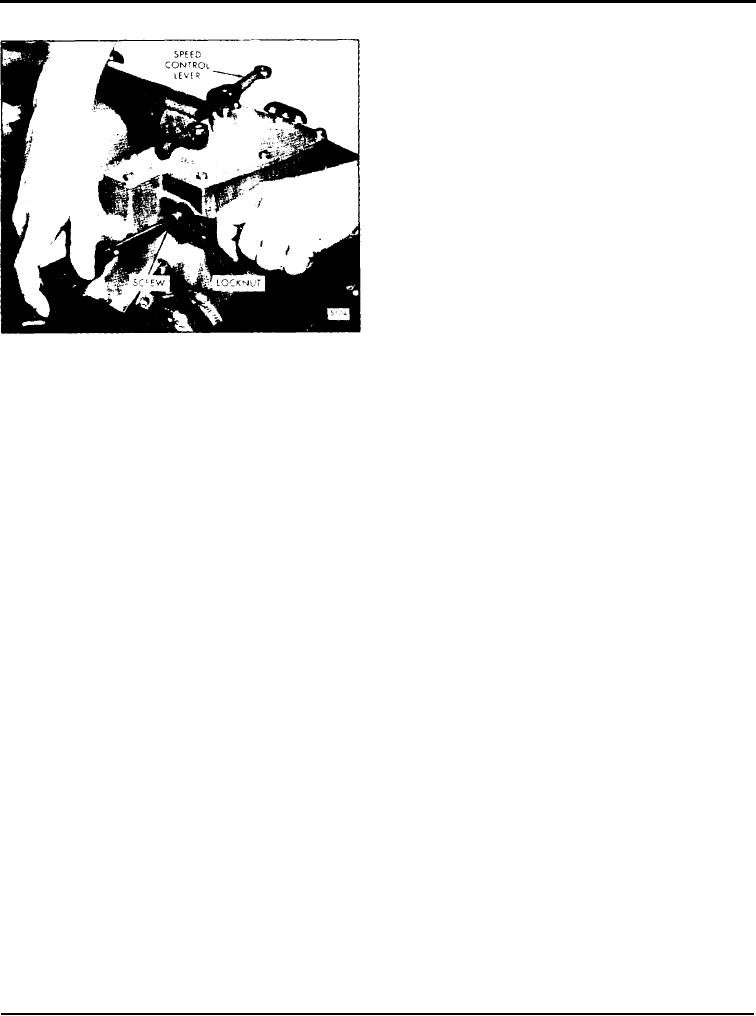

Fig. 10 - Adjusting Buffer Screw

With the idle speed properly set, adjust the buffer

lever in the maximum speed position. Turn the high-

screw as follows:

speed spring retainer until the engine is operating at

the recommended no load speed.

1 . With the engine running at normal operating

temperature, turn the buffer screw (Fig. 10) in so that

3. Hold the high speed spring retainer and tighten the

it contacts the differential lever as lightly as possible

and still eliminates engine roll.

lock nut.

NOTE: Do not increase the engine idle speed

more than 15 rpm with the buffer screw.

Adjust Idle Speed

2. Recheck the maximum no-load speed. If it has

With the maximum no load speed properly adjusted,

increased more than 25 rpm, back off the buffer screw

adjust the idle speed as follows:

until the increase is less than 25 rpm.

I. With the engine running. at normal operating

3. Hold the buffer screw and tighten the lock nut.

LIMITING SPEED MECHANICAL GOVERNOR AND INJECTOR RACK

CONTROL ADJUSTMENT

16V-71 ENGINE

The governor (Fig. 1) on the 16V engine is mounted

injector control linkage has been disturbed, the control

on and driven from the front end of the rear blower.

link levers in the governor housing and auxiliary

control link housing must be aligned before proceed-

ing with the engine tune up. Refer to Fig. 2 and

After adjusting the exhaust valves and timing the fuel

position the control link levers as follows:

injectors. adjust the governor and Injector rack control

levers.

1. Disconnect the linkage to the governor speed control

lever and stop lever.

NOTE: Before proceeding with the governor and

injector r a c k adjustments. disconnect any

2. Remove the covers from the governor housing and

supplementary governing device. After the

auxiliary control link housing.

a d j u s t m e n t s are completed, reconnet and

adjust the supplementary governing device.

3. Disconnect the adjustable link from the lever in the

auxiliary control link housing.

If the engine or governor has been overhauled, or the

Page 98