FD-30001, FD-30500, FD-30600, FD-36500, FD-37500, RD-30500,

RD-30600, RD-36500 and RD-37500 Series Drive Axles

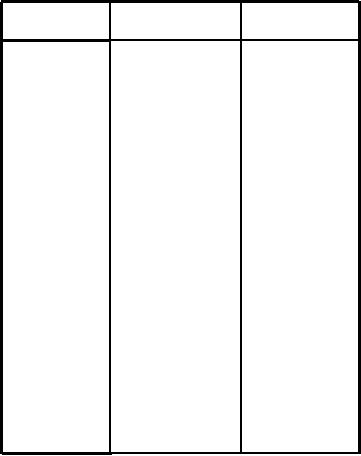

AXLE APPLICATION

DESCRIPTION

The axle assembly is a full-floating spiral bevel type with

Following is a list of axles covered in this manual and the

further reduction provided by planetary gear set within the

applicatron of these axles

wheel hub.

Model No.

Model Usage

Port NO.

PRIMARY REDUCTION

180-I(175A-I)

FD-30001-2

130192

The spiral bevel pinion and ring gear transmit power

175A-I

FD-30001-3

130269

through the center differential pinions and side gears or

110-I(175A-I)

FD-30500

130786

through a No SPlN differential to the axle shaft. The spiral

175A-I

FD-30500-1

130787

bevel differential assembly is mounted on tapered roller

FD-30500-2

180-I

130788

bearings which are adjusted by positioning of the two

FD-30001-7

175A-I

130790

threaded adjusting nuts mounted in the differential carrier

130824

FD-30500-3

110-I

and cap assembly. The tapered roller pinion bearing pre-

FD-36500-2

130998

175A-II

load is adjusted and maintained by a hardened and pre-

FD-36500-6

110-I

131403

cision ground spacer positioned between inner and outer

FD-36500-10

180-III

131507

bearings. Spacer is selected at assembly.

110-III

131569

FD-36500-11

125-III

131720

FD-30500-8

175-III,175-IIIA

131722

FD-36500-12

SECONDARY REDUCTION

125-IIIA

131927

FD-30500-12

In the wheel hub, a self-centering sun gear is spline fitted to

125-IIIA

131928

RD-30500-11

the axle shaft and drives three planetary pinion gears.

RD-36500-6

175-IIIA

131929

These gears in turn mesh with and react against a rigidly

FD-37500-4

180-III

190010

mounted internal ring gear. The planet gears rotate on

175-III, 175-III

FD-37500-5

190011

needle roller bearings mounted on hardened and ground

125-IIIA

FD-30600-2

190087

pins located in the planet carrier which in turn drives the

FD-30600-1

125-IIIA

190088

wheel hub, Positive lubrication keeps all moving parts

RD-37500-2

175-IIIA

190094

bathed in lubricant to reduce friction, heat and wear.

Brake assemblies are actuated by hardened and ground

cam shafts which in turn are actuated by air chambers

LUBRICATION

mounted externally on the axle. Air pressure is provided

to the air chambers from the air system of the vehicle when

Proper lubrication is necessary to assure long periods of

foot pressure is applied to the brake treadle valve mounted

trouble-free operation. Not only is it important that the re-

on the floorboard of the operator's compartment.

quired lubrication schedule be maintained, but also that

the proper type of lubricant be used. The following are the

Manually operated parking brakes are supplied on some

models. These consist of a brake drum, mounted on the

only lubricants recommended for use in these axles. Con-

companion flange, which encompasses a mechanically

sult applicable Operators Manual for machine model in-

volved for capacities and lubrication schedules.

operated brake shoe and lining assembly.

[5]