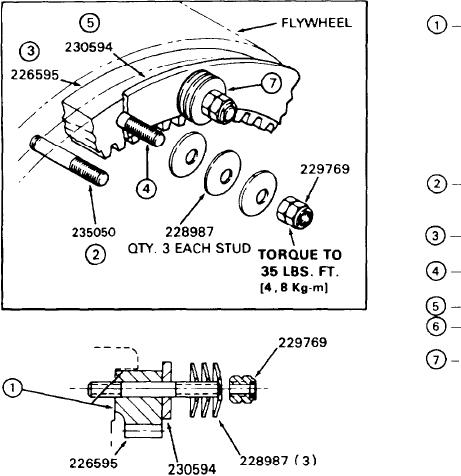

C-5000 TORQUE CONVERTER RING GEAR INSTALLATION

AND ASSEMBLY PROCEDURE

REMOVE ALL BURRS FROM FLYWHEEL MOUNT-

ING FACE & PILOT BORE, CLEAN WITH SOLVENT

THE ENGINE FLYWHEEL & HOUSING MUST CON-

FORM TO STANDARD S.A.E NO 1 - S A E J927

TOLERANCE SPECIFICATIONS FOR PILOT BORES,

ECCENTRICITIES & MOUNTING FACE DEVIATIONS.

CHECK ENGINE CRANKSHAFT "END PLAY".

MUST BE THE SAME VALUE BEFORE AND

AFTER THE TORQUE CONVERTER IS MOUNTED

TO THE ENGINE.

INSTALL THREE (3) STUDS 235050 - EQUALLY

SPACED. TIGHTEN 33 TO 36 LBS FT. [4,6-

5,0 Kg-m] OF TORQUE

INSTALL RING GEAR 226595 BY TAPPING LIGHTLY

IN PLACE.

INSTALL REMAINING STUDS TIGHTEN 33 TO 36

LBS. FT. [4,6-5.0 Kg-m] TORQUE.

INSTALL BACKING PLATE 230594

LUBRICATE STUD THREADS, BELLEVILLE WASH-

ERS & NUTS WITH S A E #10 OIL.

INSTALL BELLEVILLE WASHERS & ELASTIC STOP

NUTS AS SHOWN (3 WASHERS, EACH STUD)

TIGHTEN NUTS TO TORQUE INDICATED IN ILLUS-

TRATION ABOVE.

FLYWHEEL RING GEAR REPLACEMENT PROCEDURE

When the C-5000 flywheel ring is to be replaced order Kit No. 801874.

If the backing ring is to be replaced order Part No. 230594 backing plate.

T h e 801874 Kit Includes:

1

226595

Ring Gear

24

235050

Stud

96

228987

B e l l e v i l l e Washer

24

229769

Stud Nut

1

801949

I n s t r u c t i o n Sheet

When servicing the C-5000 flywheel ring gear with 24 bolt holes you will use 72

of the 96 belleville washers (3 on each stud) and 24 stud nuts. Tighten the nuts

t o 35 Ibs. ft. [4,8 Kg.m] torque.

-21-