TM 5-3805-258-24-1

- DIRECT INJECTION VEHICULAR ENQINE

SPECIFICATIONS

WITH SCROLL FUEL SYSTEM

FLYWHEEL RUNOUT

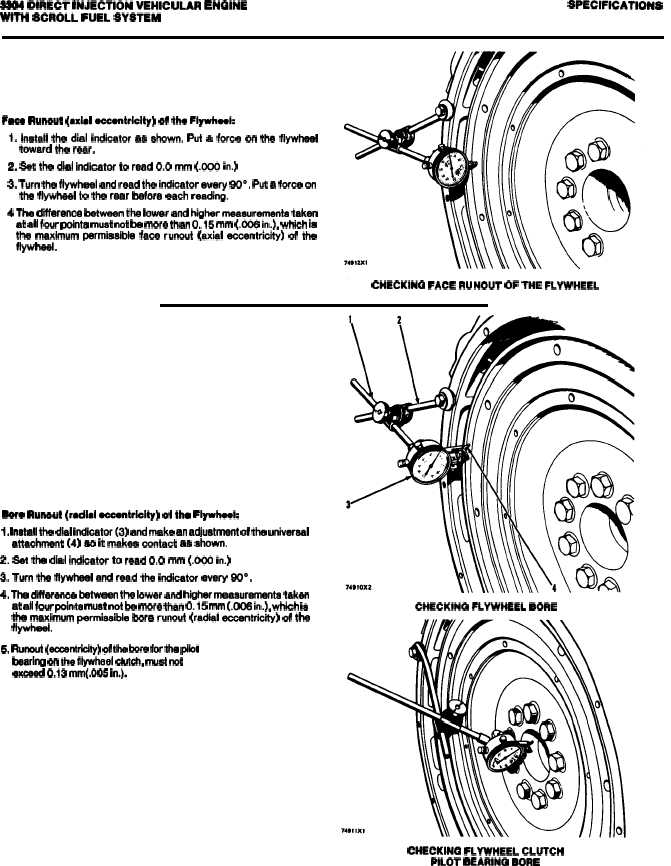

Faaa Runout (axial aaaentriclty) of tho Flywheek

1. Install the dial indicator aa shown. Put a force on the flywhaat

toward the rear.

2. Sat the dial indicator to read 0.0 mm (.000 in.)

3. Turn the flywheel and read the indicator every 90°, Put a force on

the flywheel to the rear before each reading.

4 The difference between the lower and higher measurement taken

at all four points must not be more than 0.15 mm (.006 in.), which ia

the maximum parmiaeible face runout (axial eccentricity) of the

flywheel.

CtlECKINQ FACE RUNOUT OF THE FLYWHEEL

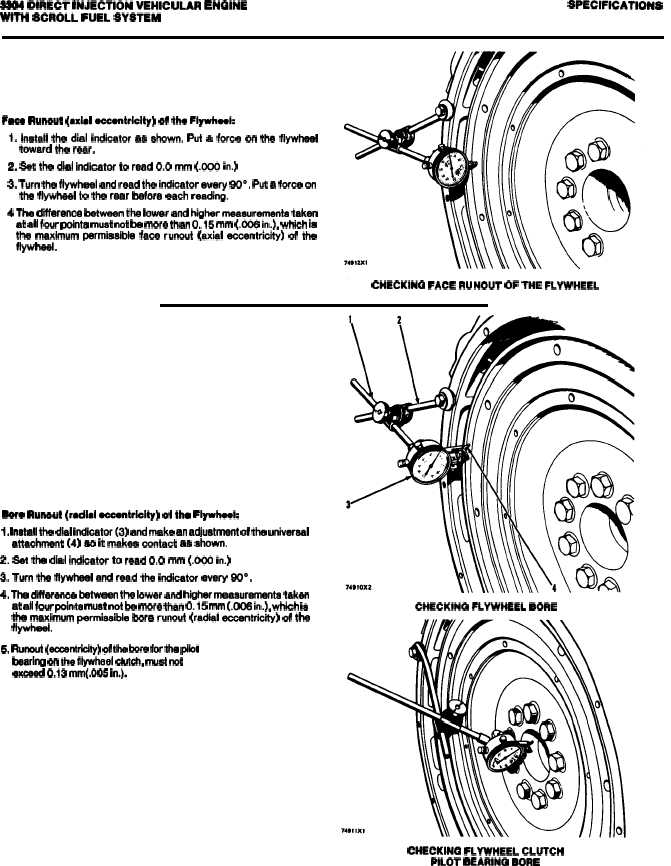

Sere RunOut (radial eccentricity) of the Flywhaek

1. Install the dial indicator(3) and make an adjustment of the universal

attachment (4) so it makea contact aa ahown.

2. Set the dial indicator to read 0.0 mm (.000 in.)

3. Turn the flywheel and read the indcator every 90°.

4. The difference between the lower and h~her meaauramants taken

at all four pcinta must not be more than 0.15 mm (.CK16 in.), wh~h is

the maximum parmiaaible bore runout (radial eccentricity) of the

flywheel.

5. Runcut @centrklfy) of the bore for the pfbt

bearing cn fhe flywheel clutch, must not

exceed 0.13 mm(.fJ05 in.).

CHECKfNG FLYWHEEL BORE

CHECKfNG FLYWHEEL CLUTCH

PILOT BEARfNG BORE

2-26