TM 5-3805-258-24-1

3S04 DIRECT INJECTION VEHICULAR ENGINE

SPECIFICATIONS

WITH SCROLL FUEL SYSTEM

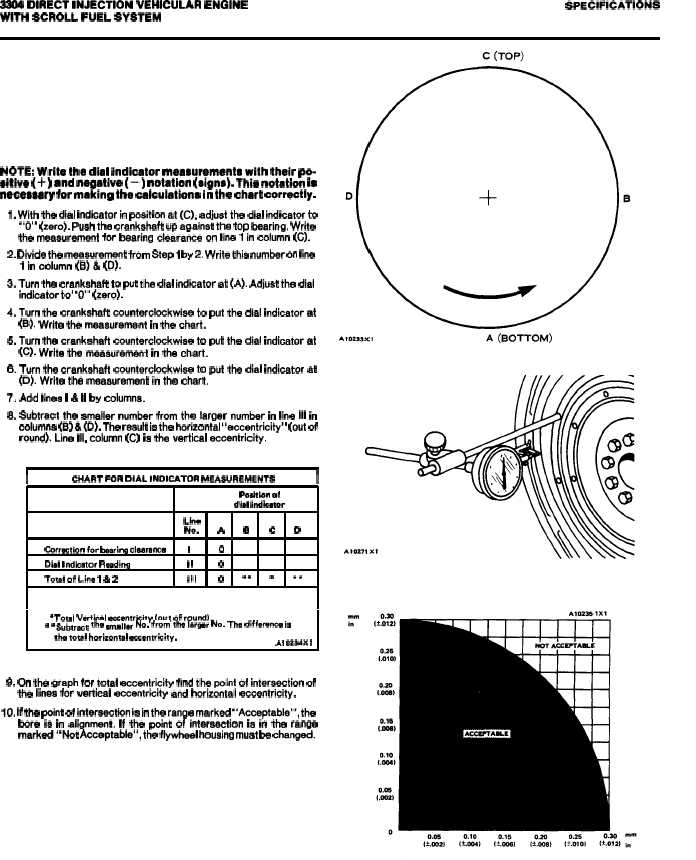

FLYWHEEL HOUSING BORE

NOTE: Write the dial indicator measurements with their po-

sitive (+) and negative (–) notation (signs). This notation is

necessary for making the calculations in the chart correctly.

1. With the dial indicator in position at (C), adjust the dial indicator to

“O” (zero). Push the crankshaft up against the top bearing. Write

the measurement for bearing clearance on line 1 in column (C).

2. Divide the measurement from Step 1 by 2. Write this number on line

1 in column (B)& (D).

3. Turn the crankshaft to put the dial indicator at (A). Adjust the dial

indicator to’ ‘O” (zero).

4. Turn the crankshaft counterclockwise to put the dial indicator at

(B). Write the measurement in the chart.

5. Turn the crankshaft counterclockwise to put the dial indicator at

(C). Write the measurement in the chart.

6. Turn the crankshaft counterclockwise to put the dial indicator at

(D). Write the measurement in the chart.

7. Add lines I & II by columns.

8. Subtract the smaller number from the larger number in line Ill in

columns (B) &(D). The result is the horizontal “eccentricity” (out of

round). Line Ill, column (C) is the vertical eccentricity.

I

CHART FOR DIAL INDICATOR MEASUREMENTS

I

Position of

did indioator

Line

No.

A

a

c

o

Cwraction for bearing cketance

I

o

Dial Indicator Raadim

II

o

Total of Line 1 & 2

Ill

o

“*

“

““

‘Total Vertical eccentricity (out of round).

. .~utirwt the ~aIIer NO. from the larger No. The diffemxe is

the total horizontal eccentrkity.

Al 0Z24X I

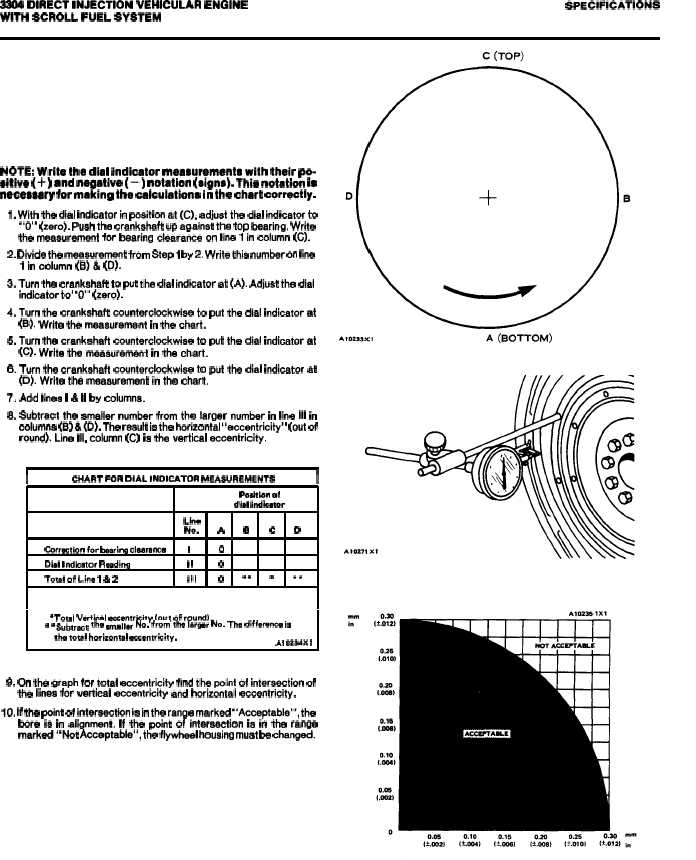

9. On the graph for total eccentricity find the point of intersection of

the lines for vertical eccentricity and horizontal eccentricity.

10. If the point of intersection is in the range marked “Acceptable”, the

bore is in alignment. If the point of intersection is in the range

marked’ ‘Not Acceptable”, the flywheel housing must be changed.

2-28