TM 5-3805-258-24-1

9506 AIR SYSTEM AND BRAKES

SPECIFICATIONS

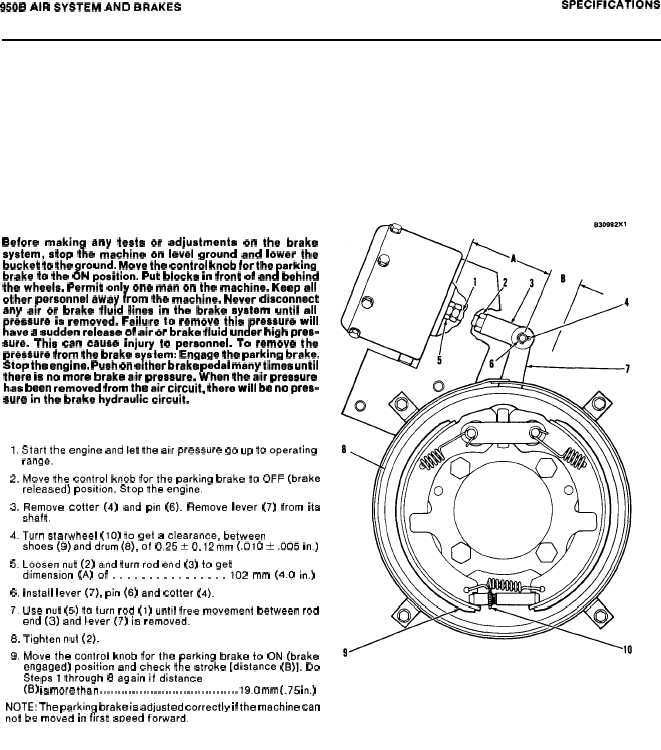

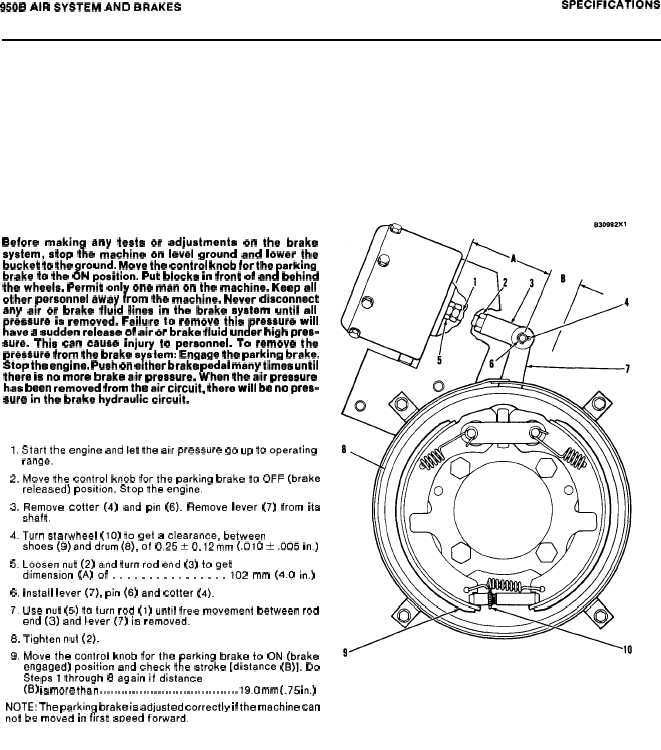

EMERGENCY AND PARKING BRAKE

ADJUSTMENT

WARNING

Before making any tests or adjustments on the brske

system, stop the mechine on Ieval ground and lower the

bucket to the ground. Move tha control knob for the parking

brake to the ON position. Put blocks in front of and behind

the wheels. Permit only one man on the machine. Keep all

other personnel away from the machine. Never disconnect

any air or brake fluid Iinea in the brake system until all

pressure is removed. Failure to remove this pressure will

have a sudden release of air or brake fluid under high pres-

sure. This can cause injury to personnel. To remova the

pressure from the brake system: Engage the parking brake.

Stop the engine. Push on either brake pedal many times until

thara is no more braka air pressure. When the air prassure

has been removed from the air circuit, there will be no pres-

sure in the brake hydraulic circuit.

1. Start the engine and let the air pressure go up to operating

range.

2. Move the control knob for the parking brake to OFF (brake

released) position, Stop the engine.

3. Remove cotter (4) and pin (6). Remove lever (7) from ita

shaft.

4. Turn starwheel (10) to get a clearance, between

shoes (9)and drum(8), of 0.25 t 0.12mm (.010 i .005 in.)

5. Loosen nut (2) and turn rod end (3) to get

dimension (A) of . . . . . . . . . . . . . . . . 102 mm (4.o in,)

6, Install lever (7), pin (6) and cotter (4),

7. Use nut (5) to turn rod (1) until free movement between rod

end (3) and lever (7) is removed.

8. Tighten nut (2).

9. Move the control knob for the parking brake to ON (brake

engaged) position and check the stroke [distance (B)]. Do

Steps 1 through 8 again if distance

(B) ia more than . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.o mm (.75 in.)

NOTE: The parking brake is adjusted correctly if the machine can

not be moved in first sDeed forward.

2-60