TM 5-3805-258-24-1

ENGINE/TRANSMISSION OIL SAMPLING

When Required

Refer to technical bulletin TB 43-0210, Appendix

F for proper oil sample intervals and detailed

sampling procedures.

CAUTION

Do not take samples after oil has been added. Oper-

ate the machine for at least 8 hours before taking a

sample.

CAUTION

Keep sampling supplies (tubing, bottle, caps, etc.)

free of any contamination. Be sure to mark sample

bottles clearly for easy identification.

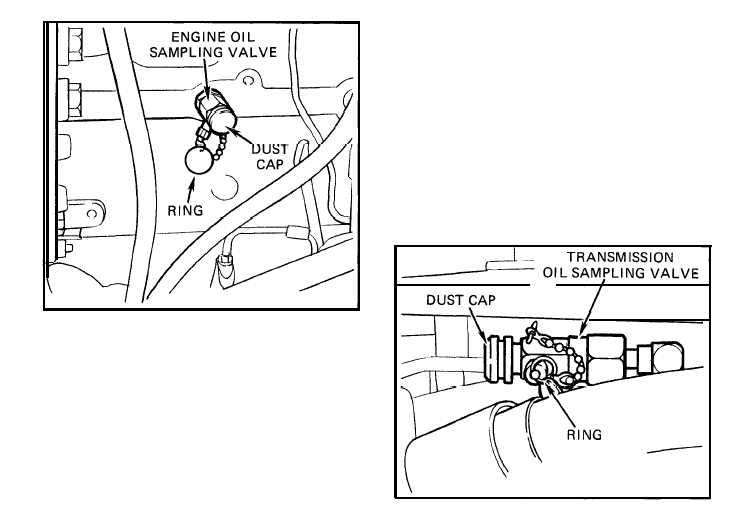

To Take Engine Oil Sample

1. Clean the engine oil sampling valve thoroughly.

Start the engine and bring up to normal operating

temperature.

2. With the engine at idle, remove the dust cap on

the oil sampling valve. Attach an appropriate size

tube to the valve if desired. Place a vessel under the

valve opening (or tube if used) and pull or turn

ring to drain about one pint of oil. Release ring

to close valve.

3. Place a sample bottle under the valve opening

(or tube if used) and fill bottle to 1/2" from top

and cap the bottle immediately. Replace the dust

cap on the sampling valve and return drained oil

to the reservoir.

4. Mark, pack and ship the bottle as described in

TB 43-0210.

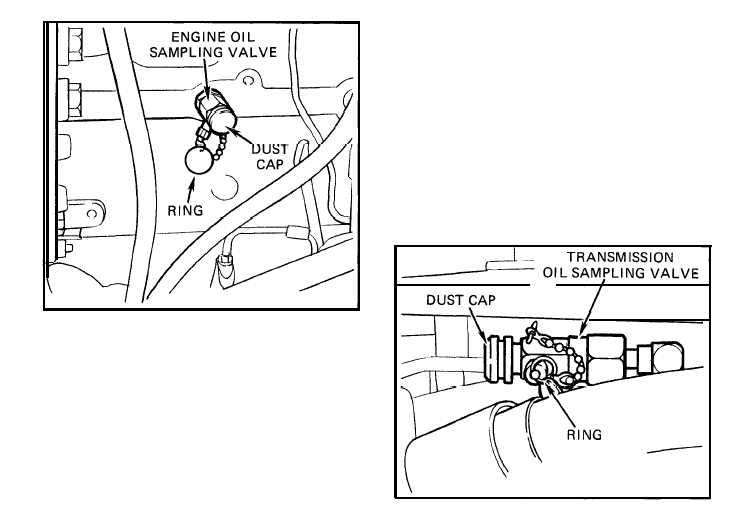

To Take Transmission Oil Sample

1. Clean the transmission oil sample valve thor-

oughly. Start the engine and drive the machine for

one mile to bring the transmission to normal oper-

ating temperature. With the engine still running,

lock the transmission in neutral and set the parking

brake.

2. Remove the dust cap on the sampling valve.

Attach an appropriate size hose to the valve if

desired. Place a vessel under the valve opening

(or hose if used) and pull or turn ring to drain

about one pint of oil. Release ring to close valve.

3. Place a sample bottle under the valve opening

(or hose if used) and fill bottle to 1/2" from top

and cap bottle immediately. Replace the dust cap

on the sampling valve and return the drained oil to

the transmission.

4. Mark, pack and ship the sample bottle as de-

scribed in TB 43-0210.

1-34.2