TM 5-3805-262-20

3-19. AIR BRAKE SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. AIR COMPRESSOR FAILS TO MAINTAIN SUFFICIENT AIR PRESSURE (Cont).

S t e p 6 . ( C o n t ).

b . I f i n l e t s c r e e n i s n o t c l o g g e d , r e i n s t a l l i n l e t s c r e e n a n d i n l et

port and secure using two lock washers and capscrews. Go to step

7 below.

Step 7. Disconnect air compressor outlet hose

f o r o b s t r u c t i o n ( c a r b o n d e p o s i t s ).

a .

b .

8. NOISY OPERATION

Step

Step

1.

2.

I f h o s e o r f i t t i n g i s o b s t r u c t e d ,

hose or fitting. Reconnect outlet

and inspect hose and fitting

remove obstructions or replace

hose to air compressor.

Reinstall air compressor (steps (b) through (m), page 7-92).

If hose or fitting is not obstructed, complete removal and re-

placement of air compressor (page 7-88).

OF AIR COMPRESSOR.

Remove engine right side panels (page 9-14).

Check for loose air compressor pulley.

a . I f p u l l e y i s l o o s e , t i g h t e n .

b. If pulley is not loose, go to step 2 below.

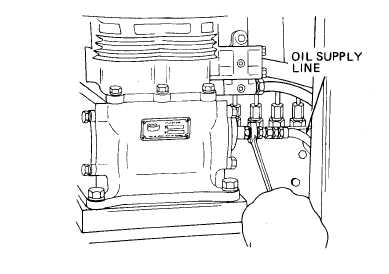

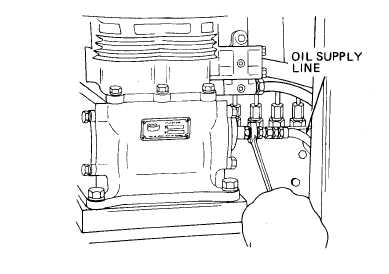

Loosen and disconnect oil supply hose from air compressor.

Loosen and disconnect other side of oil supply hose connected

cylinder block.

Check oil supply hose and fitting for restriction .

t o

3-135