TM 5-3805-262-34

[ 3-9. FRONT AND REAR AXLES MAINTENANCE (CONT) ]

d. Rear Axle.

This task covers removal and installation of rear axle.

TOOLS: No. 2 Common Organizational Maintenance Tool Kit

Safety glasses

Torque wrench, 3/4 inch drive

Socket wrench set, 3/4 inch drive

Wood blocks, two

Chain hoist

Jack stands

Roller jack

MATERIALS/PARTS: Lock nuts, eight (FSCM 10988 PN 131-1253)

REFERENCES: TM 5-3805-262-10

TM 5-3805-262-20

LO 5-3805-262-12

NOTE

PRELIMINARY PROCEDURE: Rear chassis raised and supported using jack

stands, blocks installed between trunnion assembly sides and frame; rear

drive shaft disconnected from rear axle differential assembly, rear

wheels removed, brake lines and fittings disconnected from rear axle,

and brake calipers removed (refer to TM 5-3805-262-20).

REMOVAL (SHEET 1 OF 2)

Before performing following steps, be sure that transport/service link

is in engaged position (refer to TM 5-3805-262-10) and chassis is

securely supported by jack stands. Failure to do so could cause chassis

to

(1)

(2)

(3)

(4)

fall on you causing serious injury or death.

Loosen and remove hardware securing

clamp (1). Spread clamp and remove

from hose.

Disconnect axle vent hose (2) from

adapter (3). Do this by pulling hose

straight up off adapter.

If necessary, remove adapter (3)

from rear axle (8).

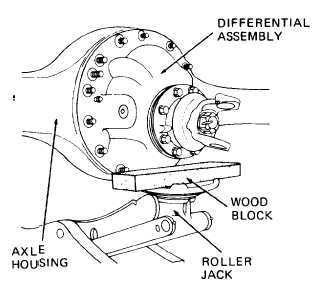

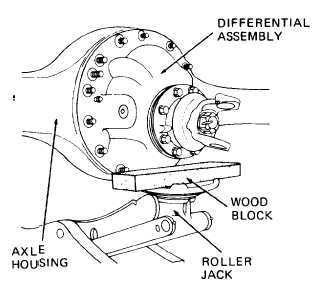

Position roller jack beneath rear

axle (8) directly under differen-

tial assembly. Raise roller jack

until rear axle is supported by

roller jack.

3-386