TM 5-3805-290-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

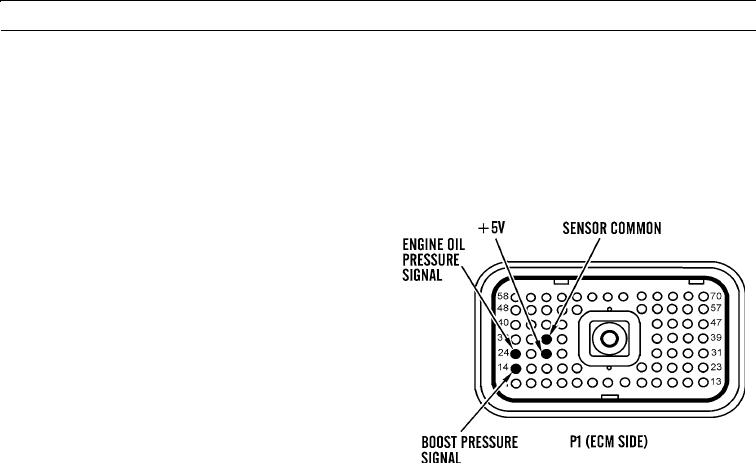

5V ENGINE PRESSURE SENSOR SUPPLY CIRCUIT TEST - CONTINUED

1.

Disconnect and inspect electrical connectors and wiring between sensor in question and ECM. Refer to Electrical Con-

nectors Inspection (WP 0022 00).

a.

P1/J1 ECM engine harness connector (WP 0170 00).

b.

P20/J20 machine interface connector (MIC) (WP 0170 00).

c.

P201/J201 engine oil pressure sensor (WP 0066 00).

d.

P200/J200 boost pressure sensor (WP 0065 00).

e.

Perform 10 lb (45 N) pull test on each wire in

ECM connector associated with +5V sensor sup-

ply:

(1)

P1-14 Boost Pressure

(2)

P1-24 Engine Oil Pressure

(3)

P1-26 +5V

(4)

P1-34 Sensor Common

427-B0668

f.

Check ECM connector (socket-head screw) for proper torque of 55 lb-in. (6 Nm).

g.

Check harness and wiring for abrasion and pinch points from sensors back to ECM.

h.

Expected Results. All connectors, pins, and sockets should be completely coupled and/or inserted and harness and

wiring should be free of corrosion, abrasion, or pinch points.

(1)

If results are OK, reconnect all connectors and proceed to step 2.

(2)

If results are not OK, replace wiring harness in question (WP 0169 00 thru WP 0175 00). Ensure seals are

properly in place and connectors are securely connected. Verify repair eliminates problem.

0013 00-6