TM 5-3805-291-10

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

INCLUDING LUBRICATION INSTRUCTIONS - CONTINUED

0012 00

Table 1. Preventive Maintenance Checks and Services (PMCS) for the 966H Wheel Loader - Continued.

LOCATION

ITEM TO

ITEM

MAN-

NOT FULLY MISSION

CHECK/

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

CAPABLE IF:

a. Tilt hood to open position (WP Hood does not open.

74

Monthly

0.2 Hour

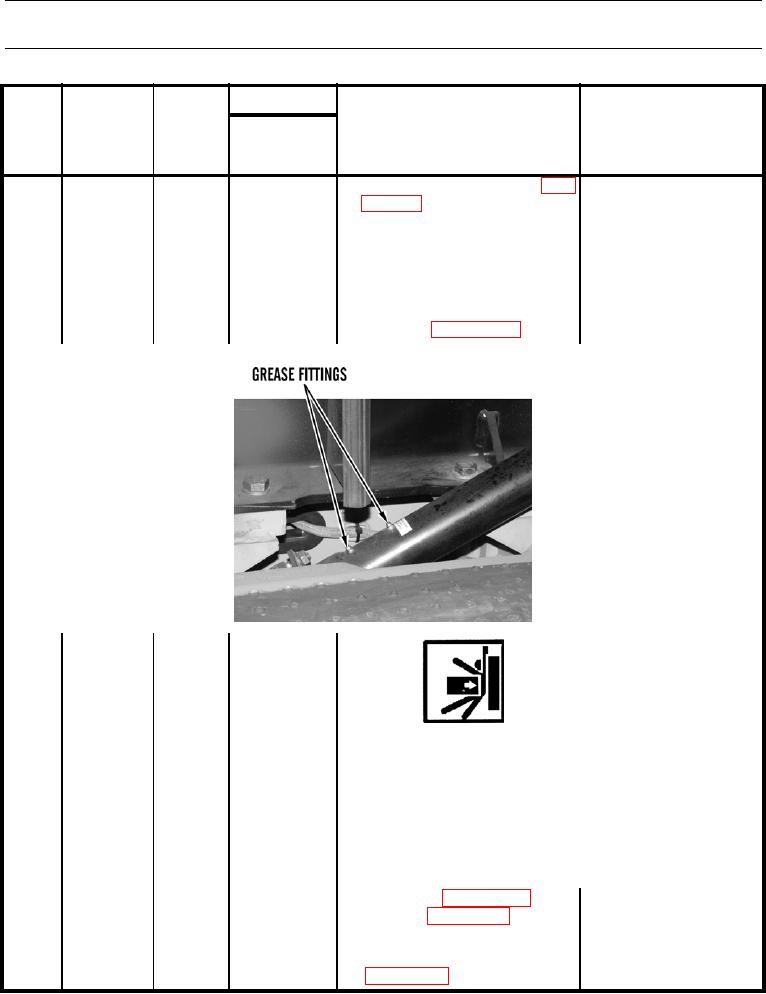

Hood Tilt

Actuator

0012 00

Grease Fit-

b. Wipe two grease fittings clean

tings

with a rag.

c. Apply GAA grease to two fittings.

Wipe off excess grease from fit-

tings.

d. Close hood (WP 0004 00).

427-C1691

75

Monthly

0.3 Hour

Drive Shaft

Spline (Cen-

ter)

WARN I N G

Stand clear of frame articulation area when machine is

operating. There is no clearance for personnel in this area

when machine turns. Crushing could occur, resulting in

injury or death to personnel.

CAU T I ON

To prevent damage to seal, fully articulate machine to the

right or to the left BEFORE lubricating drive shaft spline

(center).

a. Start engine (WP 0005 00). Raise

work tool (WP 0004 00).

b. Disengage parking brake. Fully

articulate machine right or left