TM 5-3805-291-23-2

HYDRAULIC OIL COOLER REPLACEMENT - CONTINUED

0193 00

CLEANING AND INSPECTION

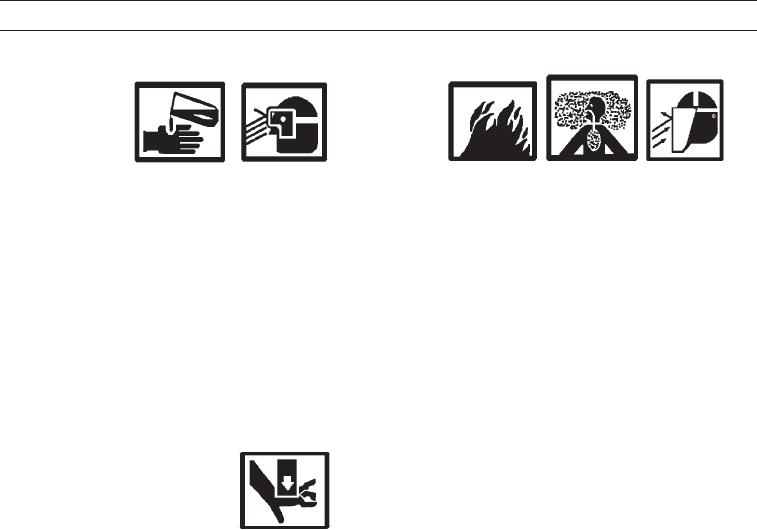

WARN I N G

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low-toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition. Failure to do so may

result in injury or death to personnel.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. DO NOT direct compressed air against human skin. Make

sure air stream is directed away from user and other personnel in the area. To prevent injury, user

must wear protective goggles or face shield. Failure to follow this warning may result in injury to per-

sonnel.

1.

Clean all parts and surfaces with solvent cleaning compound.

2.

Dry parts with compressed air.

3.

Inspect all parts for damage, wear, pitting, cracks, or corrosion and replace if necessary.

INSTALLATION

WARN I N G

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Failure to follow this warning may result in injury to personnel.

N OT E

Hydraulic and axle oil cooler core weighs 19 lb (9 kg).

Apply a thin coat of clean oil to all O-rings before installation.

1.

Position hydraulic oil cooler (11) on cooler assembly (10).

2.

Install two washers (13), bolts (12), and nuts (14) on cooler assembly (10).

3.

Install three washers (8), bolts (7), and nuts (9) on cooler assembly (10).

4.

Install new O-ring (5) in hose assembly (4). Connect hose assembly to fitting (6).

5.

Install new O-ring (2) in hose assembly (1). Connect hose assembly to fitting (3).

0193 00-3