TM 5-3805-291-23-2

REFRIGERANT HOSES, LINES, VALVES, FLANGES,

AND FITTINGS REPLACEMENT - CONTINUED

0223 00

REMOVAL - CONTINUED

C AU T I O N

Wipe area clean around all connections to be opened during removal. Cap lines and hoses and plug

openings after removing lines. Contamination of system could result in premature failure.

Use two line wrenches to avoid damage to fittings.

N OT E

Tag hoses prior to removal to ensure correct installation.

Use a container to catch any fluid that may drain from hoses or system. Dispose of fluid IAW local pol-

icy and ordinances. Ensure all spills are cleaned up.

Refrigerant is odorless. As a result, all of it may leak away and not be noticed until system stops cool-

ing. All vehicle refrigerant systems lose some refrigerant depending on the condition of the system.

Higher loss rates signal a need to locate and repair leaks.

Leaks are most often found at the compressor hose connections and at various fittings and joints in the

system. If unapproved replacement hoses are installed, refrigerant can be lost through hose perme-

ation.

Refrigerant capacity is 5.5 lb (2.4 kg).

1.

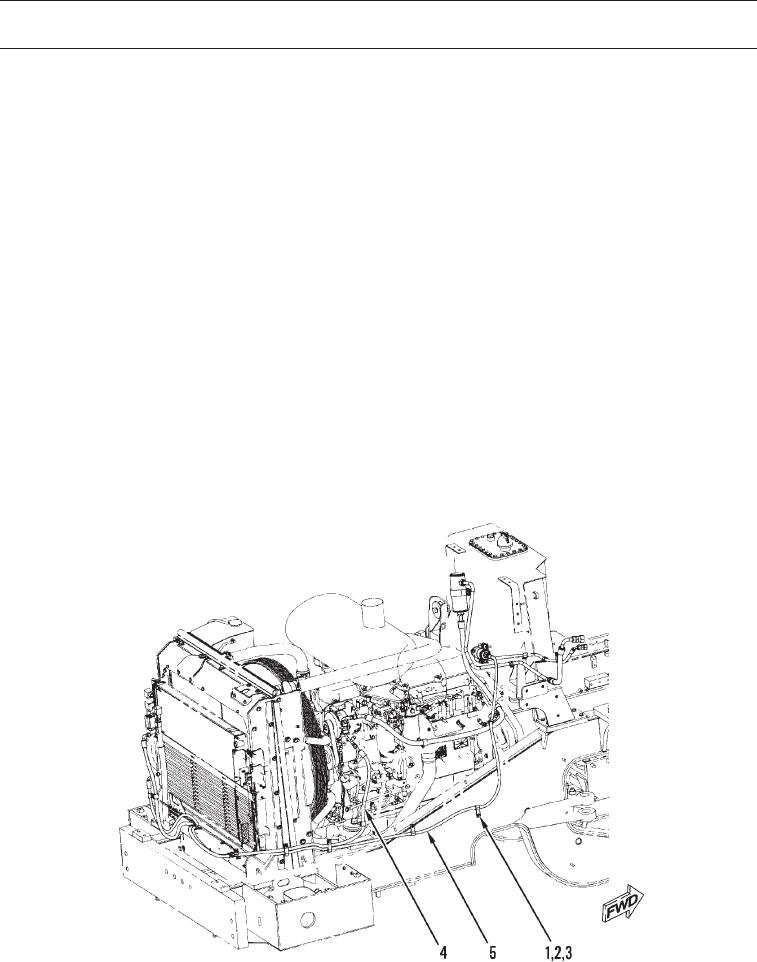

Remove nine bolts (1), washers (2), and clips (3) from hoses (4 and 5).

2.

Remove hoses (4 and 5) from machine.

427-C1250

0223 00-2