TM 5-3805-291-23-2

BUCKET LIFT ARMS REPLACEMENT - CONTINUED

0229 00

INSTALLATION

N OT E

Lower temperature of bearings for lift arm prior to installation.

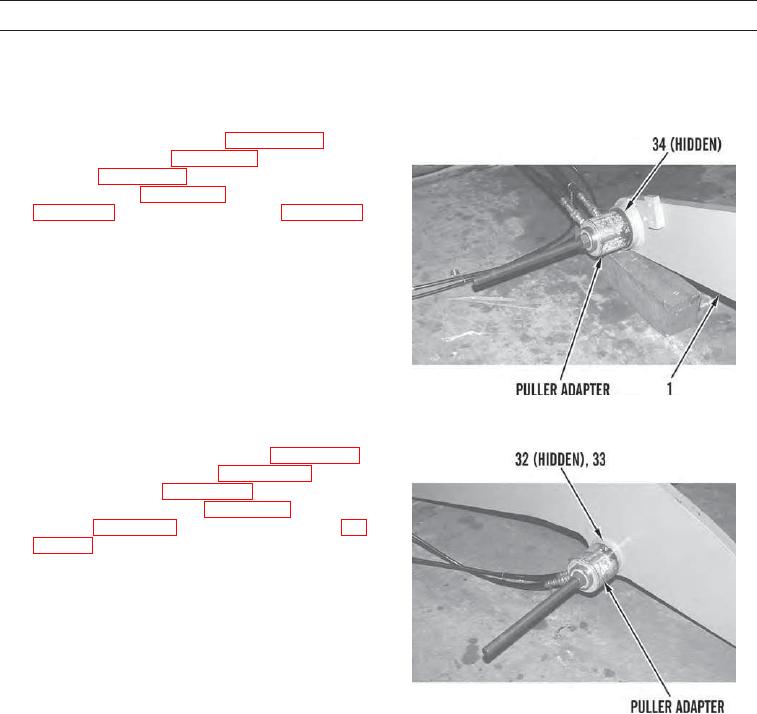

1.

Use Adapter, puller (Item 10, WP 0232 00), Nut,

plain, round (Item 47, WP 0232 00), Puller, hydraulic

(Item 52, WP 0232 00), Pump, hydraulic ram, hand

driven (Item 57, WP 0232 00), Stud, plain (Item 82,

WP 0232 00), and Washer, flat (Item 94, WP 0232 00)

to install two bearings (34) into loader frame end of

lift arm (1). Install bearings to a depth of 0.37 0.04

in. (9.5 1.0 mm).

427-C1269

2.

Use Adapter, mechanical puller (Item 5, WP 0232 00),

Nut, plain, round (Item 47, WP 0232 00), Puller,

hydraulic (Item 52, WP 0232 00), Pump, hydraulic

ram, hand driven (Item 57, WP 0232 00), Stud, plain

(Item 82, WP 0232 00), and Washer, flat (Item 94, WP

0232 00) to install two bearings (32) into lift cylinder

pin bores (33). Install bearings to a depth of 0.37

0.04 in. (9.5 1.0 mm).

427-C1270

0229 00-10