TM 5-3805-291-23-2

TORQUE LIMITS - CONTINUED

0234 00

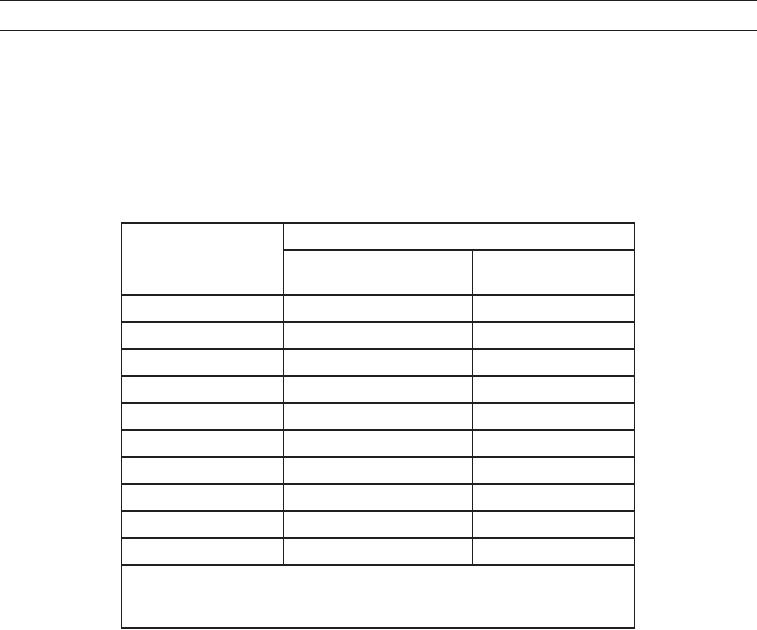

TAPERED PIPE THREAD FITTINGS

Torque is based on diameter of thread. Torque values are identical for coarse and fine threads.

N OT E

The following table has recommended standard torque value for tapered pipe thread fitting for use on Cat-

erpillar engines.

Table 18. Tapered Pipe Thread Fittings.

Standard Torque

Diameter of the Pipe

Threads with

Threads without

Thread (In.)

5P-3413 Pipe Sealant

Pipe Sealant

1/16

90 lb-in. (10 Nm)

90 lb-in. (10 Nm)

1/8

12 lb-ft (16 Nm)

12 lb-ft (16 Nm)

1/4

15 lb-ft (20 Nm)

18 lb-ft (24 Nm)

3/8

26 lb-ft (35 Nm)

33 lb-ft (45 Nm)

1/2

33 lb-ft (45 Nm)

44 lb-ft (60 Nm)

3/4

44 lb-ft (60 Nm)

55 lb-ft (75 Nm)

1

55 lb-ft (75 Nm)

65 lb-ft (88 Nm)

1 1/4

65 lb-ft (88 Nm)

80 lb-ft (108 Nm)

1 1/2

80 lb-ft (108 Nm)

95 lb-ft (129 Nm)

2

95 lb-ft (129 Nm)

120 lb-ft (163 Nm)

Note: Use 50 percent of torque values from Table 18 when fitting, plug, or port

material is nonferrous. Use 50 percent of torque values from Table 18 when tapered

thread is mating with straight thread.

0234 00-19