TM 5-3805-291-23-2

TORQUE LIMITS - CONTINUED

0234 00

HOSE CLAMPS - CONTINUED

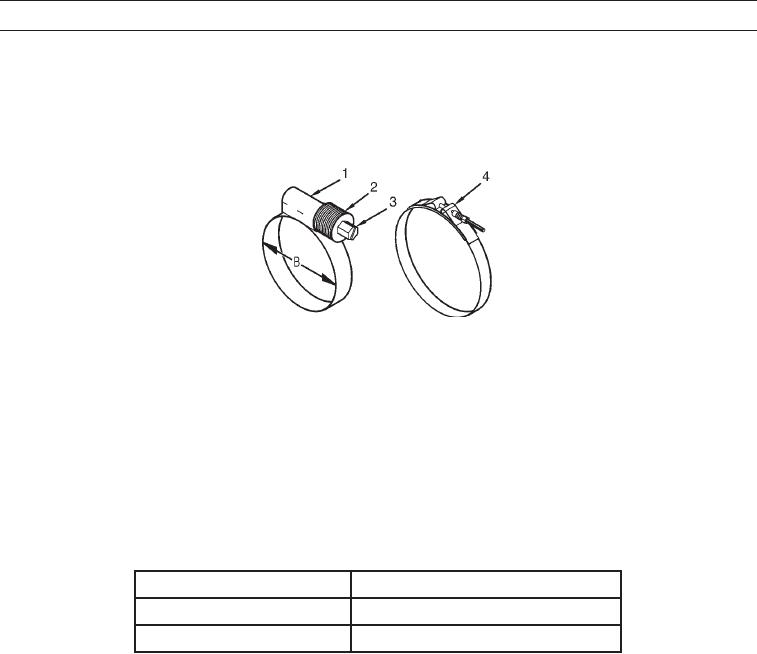

Constant Torque Hose Clamps

427-C2083

Use a constant torque hose clamp instead of any worm drive band type clamp. Ensure constant torque hose clap is the

same size as worm drive band type clamp. Because of extreme temperature changes, hose will heat set. Heat setting can cause

worm drive band type clamps to become loose. Loose hose clamps can result in leaks. There have been reports of component

failures that have been caused by loosened worm drive band type clamps. Constant torque hose clamp will help prevent these

failures.

Use a torque wrench for proper installation of all constant torque hose clamps. There are two types of constant torque

hose clamps: Belleville washer (1) and T bolt and spring (4).

When constant torque hose clamp of Belleville washer (1) is assembled correctly, Belleville washers (2) are nearly col-

lapsed flat. The proper torque for screw (3) is based on diameter (B) of clamp. Refer to the following table for the correct

torque.

Diameter (B)

Standard Torque

2 in. (Up to 50.8 mm)

65 5 lb-in. (7.3 0.6 Nm)

2 in. (Greater than 50.8 mm)

95 10 lb-in. (11 1 Nm)

The correct torque for constant torque hose clamp (T bolt and spring) (4) is 60 10 lb-in. (7 1 Nm).

END OF WORK PACKAGE

0234 00-22