TM 55-607/NAVSEA OP 3221 Rev 2

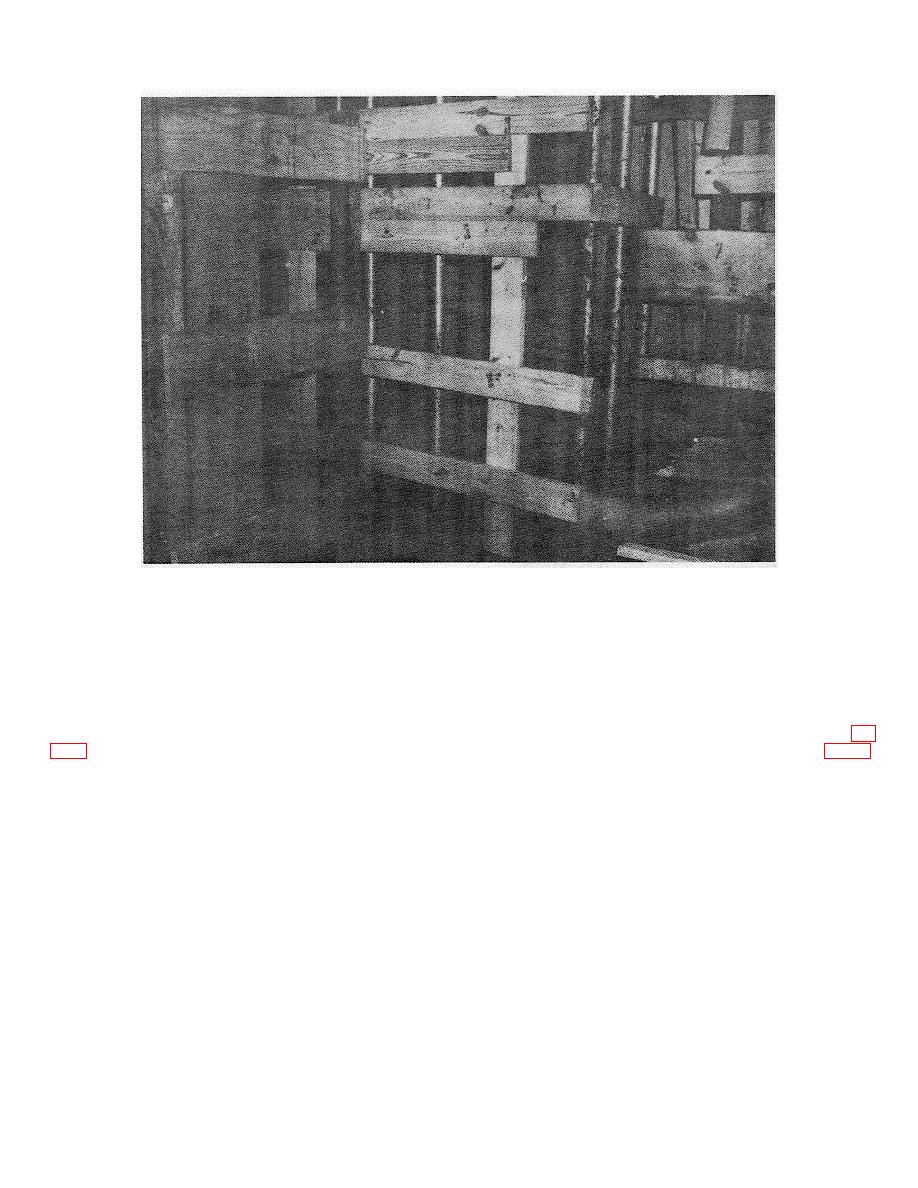

Figure 6-17. Partial encasement.

6-5. General Sawing and Nailing Practices

A secure stow is predicated upon accurate measurement and sawing of dunnage lumber and efficient use of nailing in

assembling the securing structures.

a. Sawing. Close coordination is required between the planning and installation activities to ensure that lumber is

procured in standard sizes and is used in its full dimensions, where practicable, to eliminate unnecessary sawing.

Careful procurement, supply, and selection can reduce the sawing effort, particularly in avoiding instances in which it

becomes necessary to rip long lengths of lumber onboard ship to suit specific structural applications. Many large-size

timbers (such as 4 by 4's, 2-inch planks, and 1-inch sheathing lumber) that are to be used in securing structures can be

precut by bench-mounted powersaws in dockside wood ships or sawcars to effect considerable time and cost savings (fig

6-18). Precut lumber can be assembled in the vessel, preferably in a compartment not being worked, as shown in figure

6-19. Handsaws are used for fitting lumber in areas where explosives are being stowed aboard the vessel.

6-17