TM 55-607/NAVSEA OP 3221 Rev 2

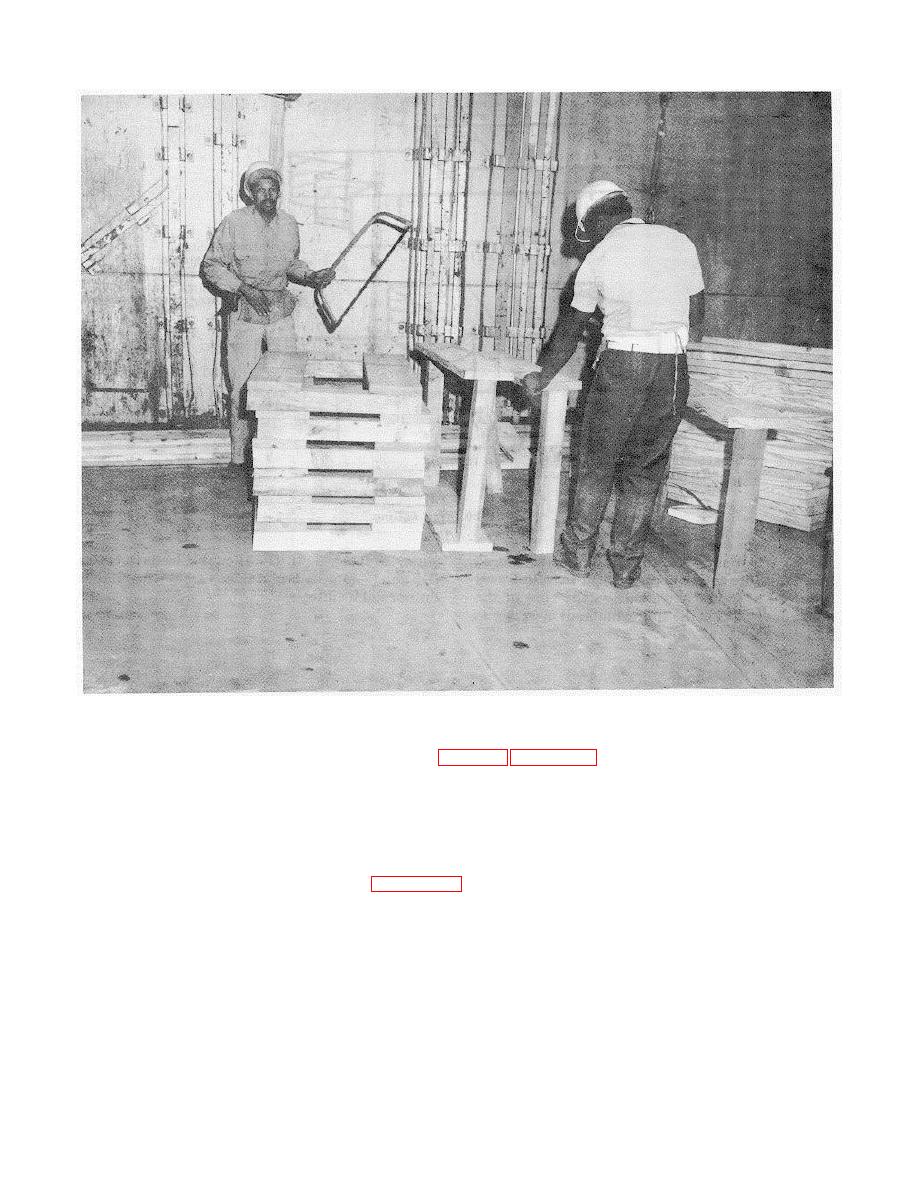

Figure 6-19. Onboard assembly of prefabricated structures.

b. Nailing. Since the integrity of the securing structure depends significantly on adequate fastening and securement

of structural members, a summary of general nailing practices is considered essential. The sizes of common wire nails

and spikes used in dunnaging operations are listed in table C-1, appendix C. The appendix also provides a detailed

summary of the types and allowable load characteristics of securing nails. The following general rules for nail selection

and nailing patterns have been developed through experience; they conform to recommendations of the 1973 edition of

the National Design Specification for Stress-Grade Lumber and Its Fastenings, published by the National Forest Products

Association.

(1) Shoring lumber is directly nailed with this method; nail heads are driven flush to the surface without the nail

point penetrating through the receiving piece. Figure 6-20 illustrates the direct nailing principle. Nail sizes should be

chosen to permit maximum penetration of the nail into but not through the receiving piece. This is particularly important

to eliminate the possibility of the nail point penetrating the boxed ammunition. A nail should not be selected if its

penetration depth is equal to the thickness of the receiving piece, as the nail point may splinter the surface and invite

personal injuries. Normally, 6 pennyweight (6d) nails are used for direct nailing of 1-inch lumber to 2 inch stock, and 8

pennyweight (8d) nails are used for joining 2-inch material without penetration through the receiving piece. When

penetration is not critical, such as when 1-inch or 2-inch lumber is nailed to 4-inch uprights, 10 or 12 pennyweight nails

are generally used.

6-19