TM 55-607/NAVSEA OP 3221 Rev 2

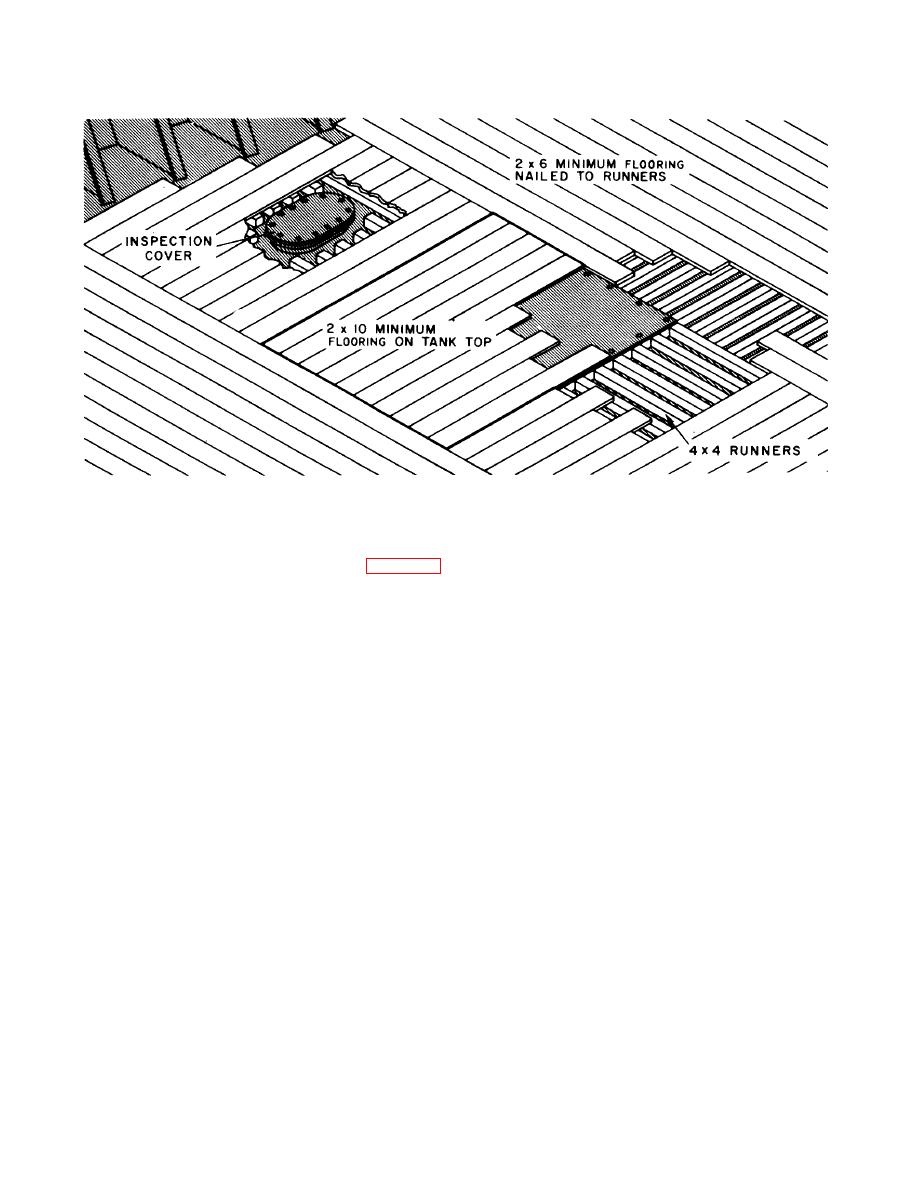

Figure 7-5. Construction details for flooring over tank top.

(4) In certain holds or compartments, unusually high brow plates (raised hatch edges) require the installation

of elevated flooring in an area adjacent to the perimeter of the hatch. This flooring is used only in an area large enough

to provide an unobstructed level surface for the safe operation of forklifts while unit loads of cargo are being stowed in an

area adjacent to the hatch level. As shown in figure 7-6, unit loads stowed fore and aft of the hatch and in the wings of

the hold may be stowed on the deck, or on strip decking, if required, only to a distance from the brow plate or hatch bevel

that will permit safe operation of the forklifts. At this point, forklifts are removed from the compartment and the elevated

flooring is installed. Usually, the flooring is laid fore and aft at the same level as the hatch, and it extends from the brow

plate or hatch bevel to the previously stowed unit loads in the wing and between the unit loads that form the alleyway.

Forklifts cannot negotiate the brow plate or hatch level when they transfer loads from the square of the hatch to the final

stowage position on the elevated flooring. Based on the type of cargo being stowed, a spacer assembly with face boards

may be required between the unit loads stowed on deck and those stowed on the elevated flooring because of the

difference in height. Such loads, which include items such as bombs, particularly those on metal pallets, and irregularly

shaped unit loads or containers, can have exposed, unsupported strapping.

7-6