TM 55-607/NAVSEA OP 3221 Rev 2

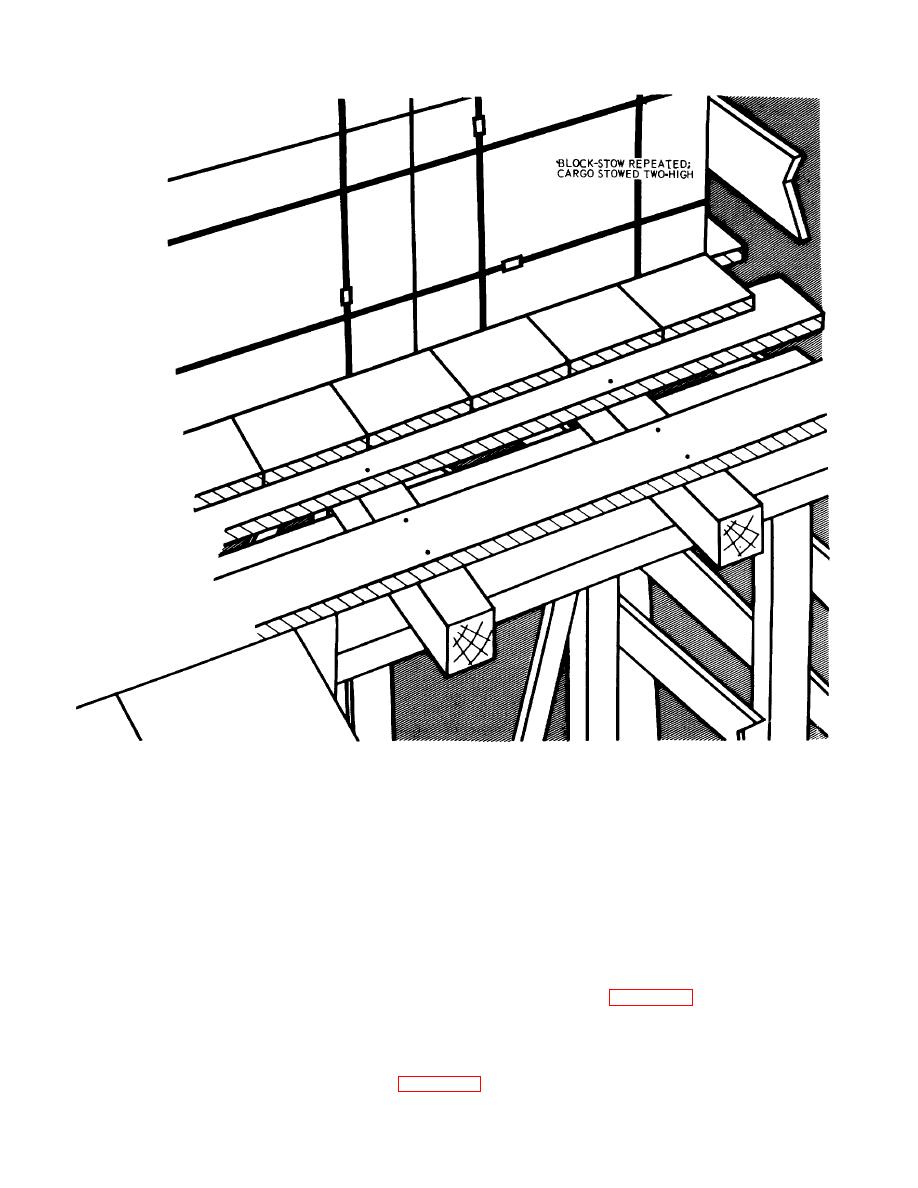

Figure 8-17. Resumption of the block-stow pattern (hull blocking technique).

8-3. Block Shoring of Cargo Voids

The occurrence of some voids within block-stowed cargo is unavoidable, due to the nonuniform sizes and configurations

of palletized ammunition and explosives. Stowage should be arranged to minimize the number and size of voids and

limit their occurrence to central areas of the compartment.

a. Voids are shored simultaneously with loading to ensure that all such areas are adequately braced. Palletized

units vary in size, and the preload prediction of location and configuration of all resulting voids is difficult. Void shoring

differs with the type of cargo being stowed, and the final construction of the securing structure can be determined only

after the emplacement of the cargo and evaluation of resulting voids.

b. Voids occurring in the block stowage of rectangular palletized loads of ammunition are typically small in size and

rectangular or square in configuration. The shoring of such voids is illustrated in figure 8-18. Pallets are stowed in the

block-stow manner, arranged to restrict voids to the central areas of the compartment. Uprights of 4 by 4-inch stock are

positioned at each corner of the void and are braced to form a secure full-block structure with 4 by 4-inch kickers. In

many cases, the cargo, while all palletized unit loads, may not be homogenous in size within the same compartment.

Such loadings often generate relatively long voids, narrow in width, and occurring between adjacently stowed rows of unit

loads different in size. These voids are indicated in figure 8-18 and are shored

8-18