TM 55-607/NAVSEA OP 3221 Rev 2

NOTE:

1. THERE ARE NO OBSTRUCTIONS IN DECK

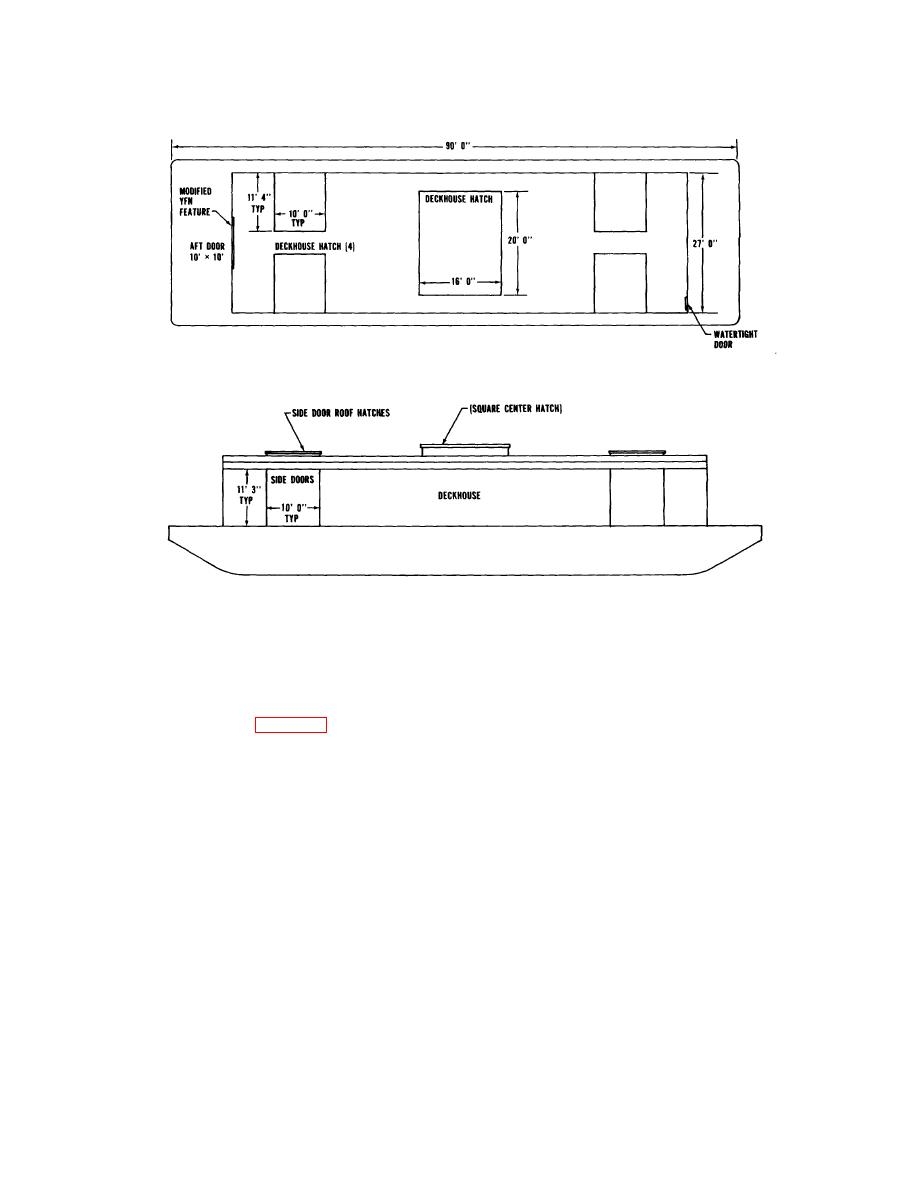

Figure 10-16. Top view of a typical YFN lighter.

Figure 10-17. Side view of a typical YFN (modified) lighter.

c. Open the hatches on the YFN and modified YFN lighters.

10-9. Dunnage Requirements

a. Sheathing. Sheathing (fig 10-18) is required to separate the ammunition cargo from the steel structure of the

barges. Since the bulwark of the YC barges and the ribbed walls of the YFN barge deckhouses do not present a level

shoring surface, the following sheathing procedures are recommended for YC and YFN barges:

(1) For YC barges, smooth sections of the steel bulwark may be sheathed with vertical 1by 6-inch boards.

Openings in the bulwark may be shored with three horizontal 4 by 4's and 2by 6-inch minimum vertical boarding to

withstand cargo forces. When barge load limits permit cargo to be stacked higher than the bulwark, the perimeter

shoring and sheathing functions can be combined into one structure. When cargo height exceeds the bulwark by more

than one-half of the top unit load, perimeter shoring of 4by 6-inch uprights, spaced not more than 36 inches apart, should

be erected. Face boards of 2by 6-inch, minimum, should then be attached to the uprights at a spacing not to exceed 24

inches.

(2) Since the steel deckhouse walls on YFN barges are not strong enough to support the loads imp sed by the

o

ammunition cargo during severe sea conditions, sheathing structures must be designed to transmit these loads directly to

the main structural beams of the deckhouse. Two different methods of sheathing YFNs are currently in use, although

both depend upon transmitting cargo forces to the three horizontal beams that are part, of the deckhouse walls. One

method calls for attaching 4 by 4's to the horizontal beams with steel strapping. Then 2by 6-inch, minimum, face boards

are attached to the 4-by-4's at a spacing not

10-19