TM 55-607/NAVSEA OP 3221 Rev 2

to exceed 2 inches. The closely spaced face boards allow this sheathing structure to interface with unit loads of various

configurations without any modifications. The other method calls for the use of 4by 4-inch, minimum, uprights, spaced 6

feet apart, with 2by 12-inch face boards, spaced to fit the configuration of the cargo to be stowed against it.

(3) Since these barges have steel decks, all ammunition unit loads with steel pallets require 1b 6-inch

y

minimum strip decking to prevent metal-to-metal contact.

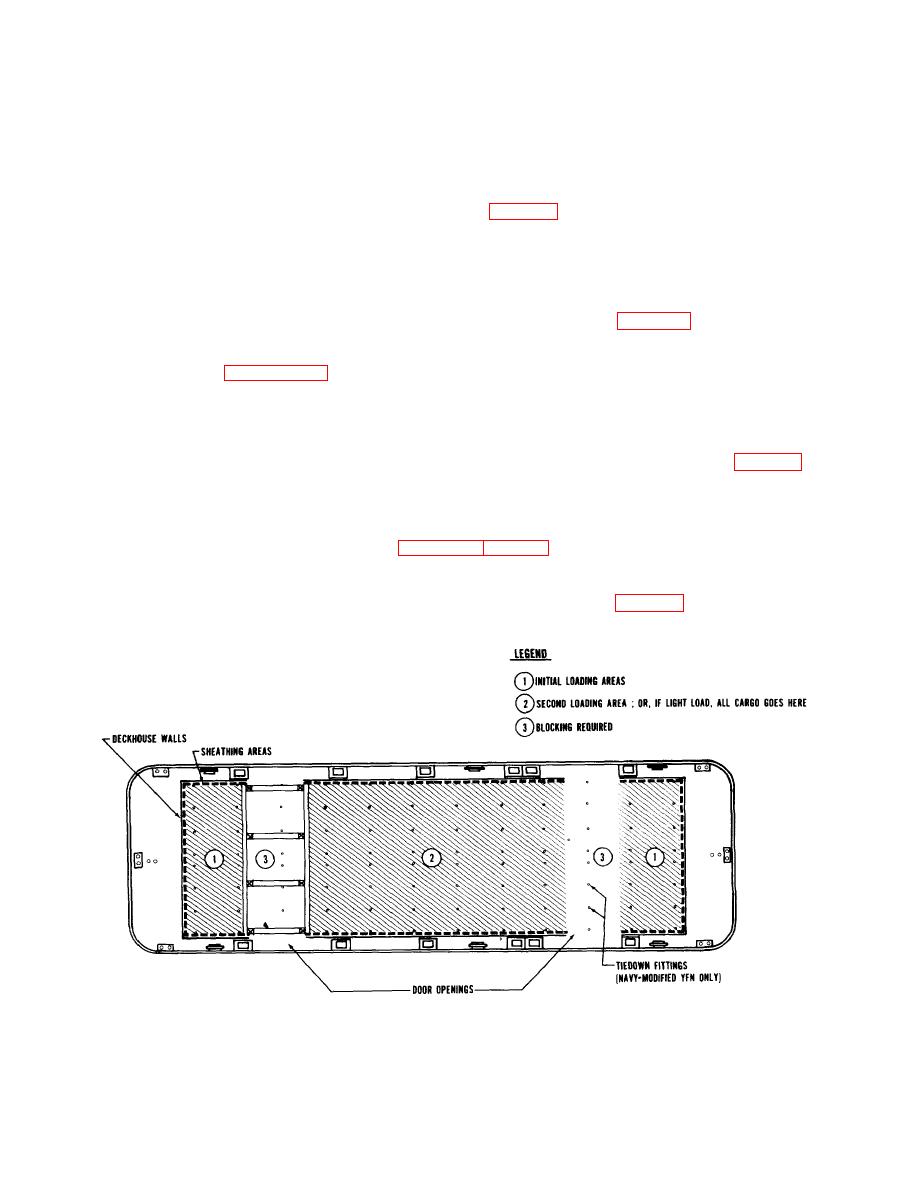

b. Void Shoring. Normal loading practice for YCs and YFNs (fig 10-18) is to start cargo stowage at the fore and( aft

bulkheads and work toward the center. On YFNs, however, cargo is not normally stowed adjacent to the doors; it is

stowed in the center area between both sets of doors. For lightly loaded YFNs, it may be preferred to load only the

center portion of the barge. Shoring of the voids within the cargo stow should be in accordance with the following

guidelines:

(1) For one-high stowage, all voids must be fully blocked as detailed in chapter 8. Similarly, all void space

must be shored for block stowage of cargo more than one unit load high. For voids distributed throughout the stow based

on the sweatboard-to-sweatboard technique, full blocking is required only for top layer voids. Lower layer voids should

be shored as indicated in paragraph 8-4c.

(2) The void areas between doors on YFNs and at the end of cargo stows on all barges can be shored with

deck framing if cargo is one unit load high, or with the appropriate bulkhead structure if cargo is two or more unit loads

high. Normally, for one-high stowage, 4by 4-inch bearers are placed against the cargo or barge structure and kicked with

4by 4inch kickers spaced the width of the unit loads, or not more than every 6 feet. It may be more desirable to shore

directly off the cargo for overhanging unit loads. In this case, larger dunnage, such as the 2 by 12's (fig 10-18) should be

used for bearers. However, care should be taken to make sure the kickers are sized to contact the bearers in the area

that is against the cargo. For cargo that is stowed more than one-high, nonheat bulkhead structures should be

constructed and kicked against each other o;, as appropriate, barge structures as dictated by the situation. The kicking

can be accomplished with horizontal 4by 4-inch kickers at the top and bottom of each tier of unit loads, or with the

diagonal brace "A" or frame structures illustrated in figures 7-15 and 7-16.

(3) Shoring structures should not be run to the side doors on YFN barges because the doors are not strong

enough to resist the cargo forces that could be imposed on them. For maximum strength, both sheathing and blocking

structures should be directed to the vertical steel beams on either side of the doors (fig 10-19).

Figure 10-18. Sheath i g and loading areas.

10-20