TM 5-2420-231-23-3

0371

HOW ADAPTERS AFFECT TORQUE LIMITS CONTINUED

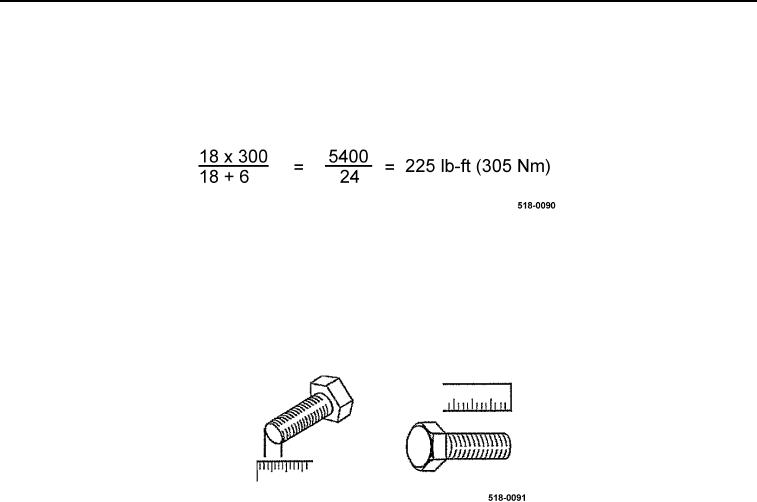

For example:

A 6-inch extension is used on an 18-inch torque wrench. The required torque is 300 lb-ft (407 Nm).

Using the formula, the torque wrench setting can be determined:

Figure 6. Torque Calculation Example.

0371

Therefore, a torque wrench setting of 225 lb-ft (305 Nm) will result in the required torque of 300 lb-ft (407 Nm).

HOW TO USE TORQUE TABLES

0371

Figure 7. Measuring a Bolt.

0371

1. Measure the diameter of the bolt you are installing.

NOTE

Threads-per-inch measurement applies to SAE standard fasteners only (Table 1).

2. Count the number of threads per inch or use a pitch gauge.

3. Look down the left-hand column and find the diameter and number of threads per inch of the bolt you are

installing.

4. Find the torque value for the grade of bolt you are installing.