TM 5-3805-255-14

0013

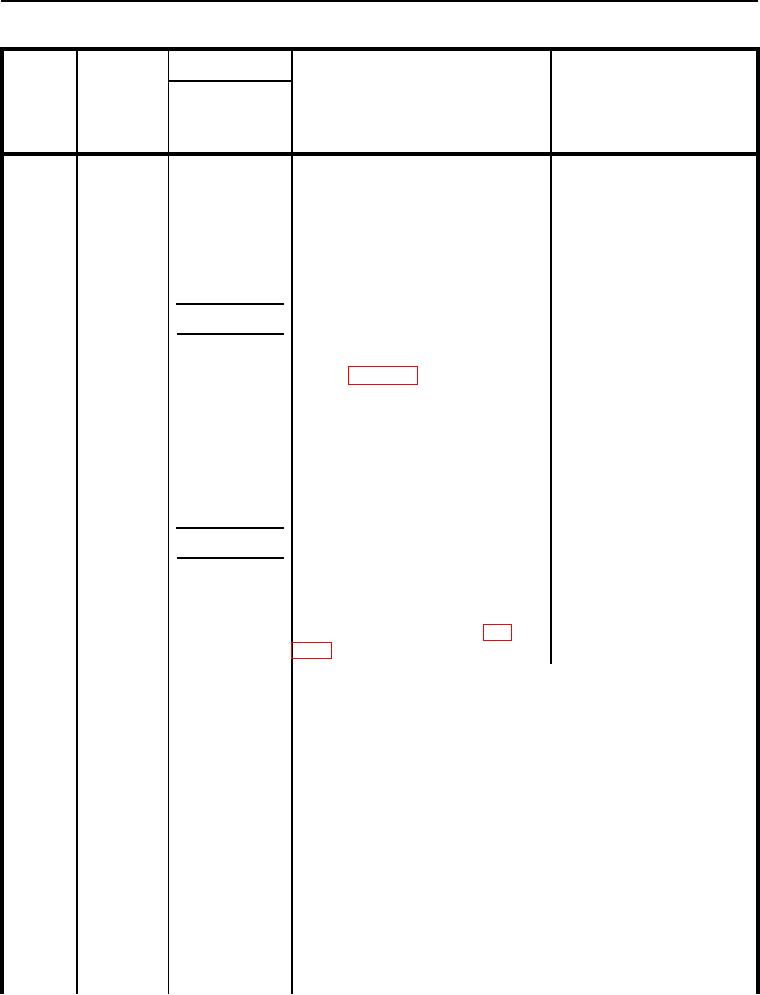

Table 1. Preventive Maintenance Checks and Services (PMCS) for H100C - Continued.

.

LOCATION

ITEM TO

NOT FULLY MISSION

CHECK/

SERVICE

ITEM NO. INTERVAL

CAPABLE IF:

PROCEDURE

Before

Hydraulic

c. If hydraulic oil level is low, add

17

Reservoir Oil

clean hydraulic oil as necessary.

(Cont.)

Level

Refer to Table 2, Lubricants, in this

work package for grade and quantity

of fluid required.

d. Install filler cap and hydraulic oil

level gauge.

RIGHT FRONT

Before

Right Front Tire

a. Check tire for correct inflation.

Tire does not hold pressure.

18

Refer to WP 0002 for pressure

specifications.

b. Check for missing bolts.

Two or more bolts missing.

Damage to tire that would

c. Check tread and sidewall for cuts

lead to tire failure is evident.

and foreign material in treads.

d. Check backside of wheel for oil

Class III oil leaks are evident.

leaks from final drive.

CAB INTERIOR

During

Gauges and

During startup and operation, monitor Gauge indicates system

19

Warning Indicator all gauges and warning indicator lights failure.

Lights

for any information that would require

engine or loader shut down (WP

After

Cleaning Loader

CAUTION

20

Remove dirt from engine, transmission, hydraulic cylinders,

axle, and hydraulic connections. If allowed to accumulate, dirt

will find its way into loader components when plugs and covers

are removed. Dirt caked over axle transmission and engine

breathers will cause oil losses.

Steam is the most effective means of cleaning dirty equipment.

If steam is not available, use a spray of mineral spirits or a

similar solvent. Steam can be harmful to electrical

components. Protect the generator or alternator and cranking

motor openings from the full force of the steam jet. If a solvent

spray is used, it must not be injurious to the hydraulic hoses,

engine fuel lines, or the insulation on electric wires. Apply fresh

grease at all fittings on the loader after cleaning.

0013-16