TM 5-3805-255-14

0018

Table 1. Field PMCS for the H100C Loader - (Continued).

LOCATION

ITEM TO

NOT FULLY MISSION

CHECK/

SERVICE

CAPABLE IF:

ITEM NO. INTERVAL

PROCEDURE

Monthly

Air Compressor

7

Belt Adjustment

(Cont.)

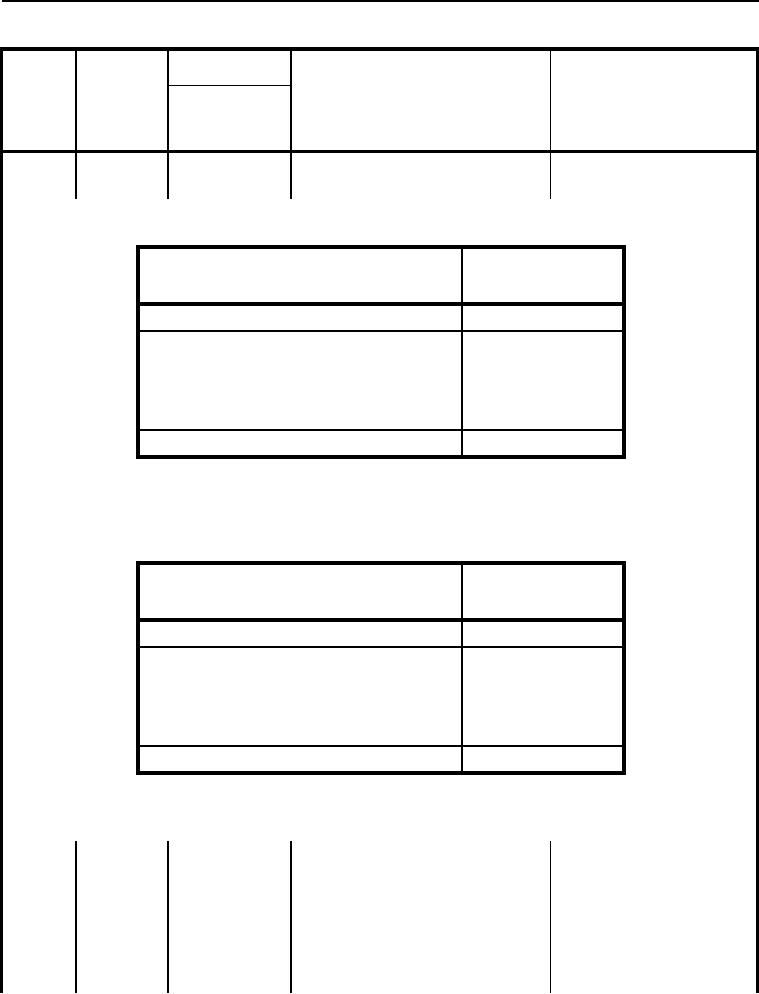

Table 2. Belt Tension Chart.

AIR COMPRESSOR

BELT

CONDITION

New Belt Installation

95 to 100 lb

New Machine Upon Delivery

80 to 85 lb

1 Hour After Belt Replacement

After 10 Hours of Operation

After 50 Hours of Operation

At Intervals of 200 Hours

Minimum Permissible Tension

60 lb

Table 3. Belt Tension Chart (Deflection Method).

AIR COMPRESSOR

BELT

CONDITION

New Belt Installation

3/4 in. (19 mm)

New Machine Upon Delivery

13/16 in.

1 Hour After Belt Replacement

( 21 mm)

After 10 Hours of Operation

After 50 Hours of Operation

At Intervals of 200 Hours

Minimum Permissible Tension

7/8 in. (22 mm)

Biennially

Starter

Starter must be lubricated every

Broken motor housing or gear.

8

Lubrication

5,000 hours under normal starting

conditions, or sooner, should it

become necessary to remove motor in

process of engine servicing.

0018-8