TM 5-3805-255-14

0088

FRONT MAIN OIL SEAL REPLACEMENT CONTINUED

00088

4. Remove oil seal from front cover. Thoroughly clean seal bore in housing and remove any nicks and scratches.

5. Install new oil seal. Use a tool of sufficient diameter to press on outside diameter of seal.

6. Inspect viscous vibration damper for following:

a. Dents. Even small dents can cause inner space member, which floats in silicone fluid, to contact outer

housing. Such contact can cause damper malfunction. Replace dented dampers.

b. Leaks. Clean damper thoroughly and inspect for silicone fluid leaks. Such leaks can occur at cracks or

seam openings in housing. Replace damper if any leaks are found.

NOTE

Viscous dampers are designed to operate for as many hours or miles as other major

engine components. Therefore, except for those cases mentioned above, dampers do not

need to be replaced except at major overhauls.

7. If crankcase front plate was removed, reinstall as follows:

a. Install a new gasket on front of crankcase and install front plate with hydraulic pump attached. Secure front

plate with capscrews and locks.

b. If equipped with hydraulic pump, connect oil line manifold to pump.

c.

Install adapter housing with injection pump attached. Secure adapter housing to crankcase front plate.

Secure injection pump to mounting block. Connect all lines to injection pump.

d. Install lubricating oil and water pump assembly (WP 0098).

8. Install crankshaft gear key on crankshaft.

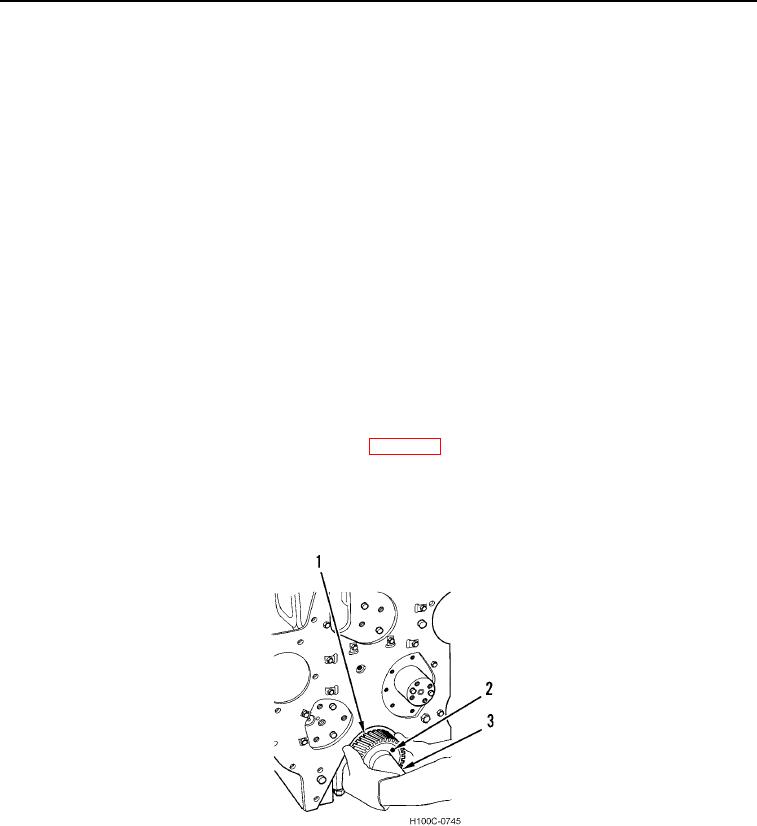

9. Heat crankshaft gear (Figure 4, Item 1) to 475F (245C). Using suitable heat-resistant gloves, install gear on

crankshaft with timing mark facing out.

Figure 4. Installing Crankshaft Gear.

0088

0088-8