TM 5-3805-255-14

0089

CLEANING, INSPECTION, AND REPAIR

00089

Cylinder Head

00089

1. Clean cylinder head (Figure 11, Item 2) and crankcase deck thoroughly. Carbon must be removed from bottom

face of cylinder head, out of valve ports, and flush out water passages to remove any accumulation of salt,

lime, or sludge.

2. Check cylinder head for flatness. Use a feeler gauge and a straightedge long enough to span length and width

of cylinder head. If more than a 0.003 in. (0.08 mm) feeler gauge can be inserted under straightedge, resurface

cylinder head to a maximum of 0.030 in. (0.08 mm) if necessary. After resurfacing head, surface must have a

smoothness of 0.001 in. (0.003 mm) or less with a wave pattern or no more than 3 in. (76 mm).

NOTE

Crankcase deck cannot be resurfaced.

3. Check cylinder head height before resurfacing. Cylinder head height should be 4.998 to 5.002 in. (126.95 to

127.05 mm) with a minimum allowable reconditioned height of 4.968 in. (126.19 mm). If height is at minimum

allowable reconditioned height, further resurfacing cannot be done and it will be necessary to replace cylinder

head.

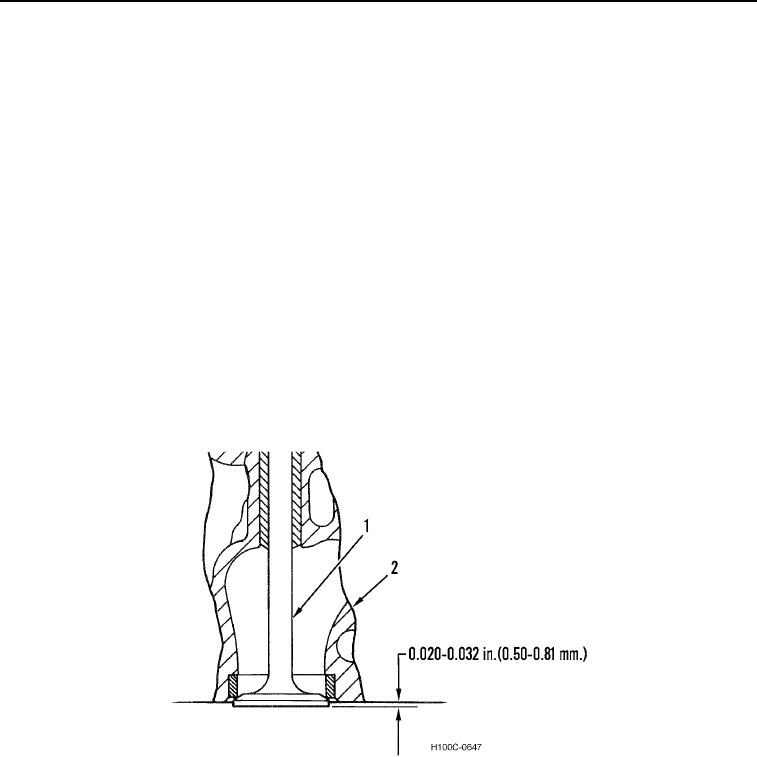

4. If cylinder head needs to be resurfaced, protrusion of valves (Figure 11, Item 1) must be maintained. Allowable

valve protrusion from cylinder head (Figure 11, Item 2) face is 0.020 to 0.032 in. (0.50 to 0.81 mm), and

minimum allowable protrusion is 0.010 in. (0.25 mm).

Figure 11. Valve Protrusion from Cylinder Head.

0089

0089-12