TM 5-3805-255-14

0089

CLEANING, INSPECTION, AND REPAIR CONTINUED

Cylinder Head Pressure Check

00089

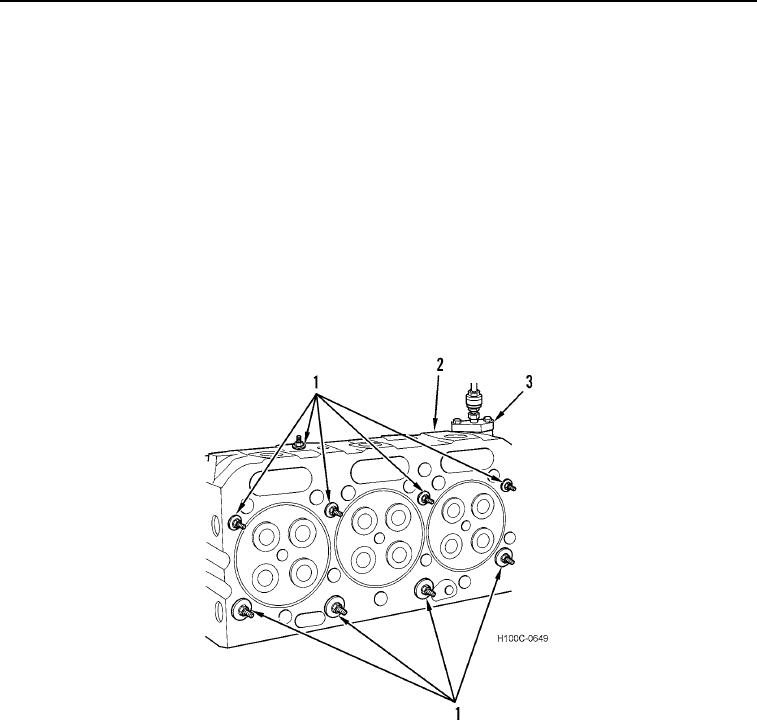

With injection nozzles installed and valves removed, pressure check cylinder heads (Figure 14) as follows:

a. Install rubber stoppers (Figure 13, Item 1) and special adapter (Figure 13, Item 3), from test kit PLT-508 or

use fabricated plates like those shown in (Figure 14, Figure 15, and Figure 16).

NOTE

Fabricate pressure plate (Figure 14) from 0.500 in. (13 mm) plywood, side plates from

0.250 in. (6 mm) steel, and a gasket for each plate from 0.125 in. (3 mm) rubber.

A kit consisting of thicker cylinder head gasket grommet inserts is available for use when

cylinder head or crankcase is eroded in water passage areas. Remove existing grommets

from new cylinder head gaskets and replace with grommets furnished in kit.

b. Fill cylinder head (Figure 13, Item 2) with hot water. Apply 10 to 12 psi (69 to 83 kPa) air pressure and

check for leaks.

Figure 13. Cylinder Head Pressure Check.

0089

0089-14