TM 5-3805-255-14

0089

CLEANING, INSPECTION, AND REPAIR CONTINUED

Valve Lever and Lever Shaft Assembly

00089

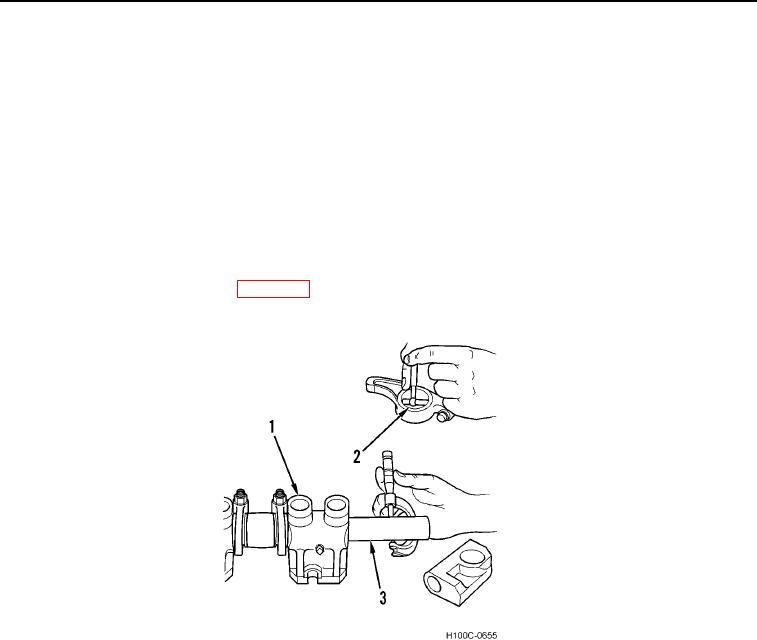

1. Wash all parts in a cleaning solvent and dry thoroughly with compressed air. Be sure drilled oil passages in

lever shaft (Figure 21, Item 3), intermediate brackets (Figure 21, Item 1), and lever bushings (Figure 21,

Item 2) are open. Also clean out oil passages in push rods.

2. Check outside diameter of valve lever shaft (Figure 21, Item 3) with a micrometer. Check inside diameter of

valve lever bushings (Figure 21, Item 2) with telescoping gauge. Difference between these two readings is

running clearance. If clearance is greater than 0.001 to 0.003 in. (0.03 to 0.08 mm) with a maximum allowable

clearance of 0.006 in. (0.15 mm), replace worn parts.

3. When replacing lever bushings (Figure 21, Item 2), be certain that oil hole in bushing aligns with oil hole in

lever. Bore or hone bushings to 1.4220 to 1.4235 in. (36.119 to 35.157 mm).

4. Inspect valve stem contact pad surface of valve levers and replace if wear is severe.

5. Remove and recondition valves (WP 0086).

Figure 21. Checking Valve Lever Bushing and Shaft for Wear.

0089

Injector Nozzle Lines

00089

Blow compressed air through injector nozzle supply and return lines to be sure they are clean.

END OF TASK

0089-21