6. Alternately tack weld cutting edge to bucket

1. Align and clamp straight edge so that back

sheet on top.

e d g e will line up with front edge of bucket

sheet as shown in view "B".

7. Remove flat plates and continuously weld cut-

ting edge to bucket sheet on top, as shown in

2. Measure up on each side cutting edge the length

views "C" and "D". Top weld (12) is a 3/16 inch

of the line segment (2) from top cutting edge

flush bevel groove weld.

and scribe lines (1) as shown in view "A".

8. Clamp side cutting edges flush against bucket

3 . Guide cutting torch through scribe lines (1)

end plate, bucket sheet and top cutting edge

and down rear of side cutting edges to top cut-

and weld, (9 & 10) view "C", securely. Welds

ting edge as shown in view "A" ; then continue

to bucket end plate are 1/4 inch convex bevel

cutting along back side of straight edge(s) as

groove weld inside and 3/8 inch fillet weld out-

shown in view "B". Remove and discard cutout

side. Welds to cutting edge and bucket sheet

section from bucket. Grind all rough edges on

are 3/4 inch fillet weld inside and 5/8 inch flush

bucket smooth.

bevel groove weld outside. Where the side cut-

ting edge overlaps the bucket sheet on the out-

4. Equally space three flat plates on bucket sheet

side a 3/8 inch fillet weld should be made.

and tack weld in three places as shown in view

"C".

Note: Use a 3/16 inch diameter low hydrogen

electrode equivalent to AWS-E-10016.

5. Position and align new cutting edge assembly

9. Grind all welds inside bucket to present a

flush against bucket sheet and flat plates and

smooth surface for entry of material ; grind the

secure in place with clamps as shown in view

"C".

residue of the tack welds from bucket sheet.

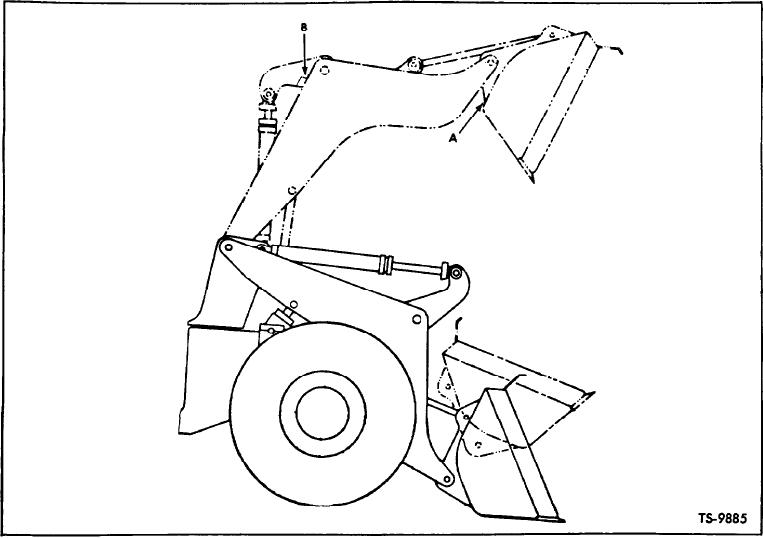

Fig. 43.

Check and Adjust Boom to Bucket Linkage

[45-06-2]