to Parts Manual for applicable part numbers.

1000 HOUR MAINTENANCE OPERATIONS

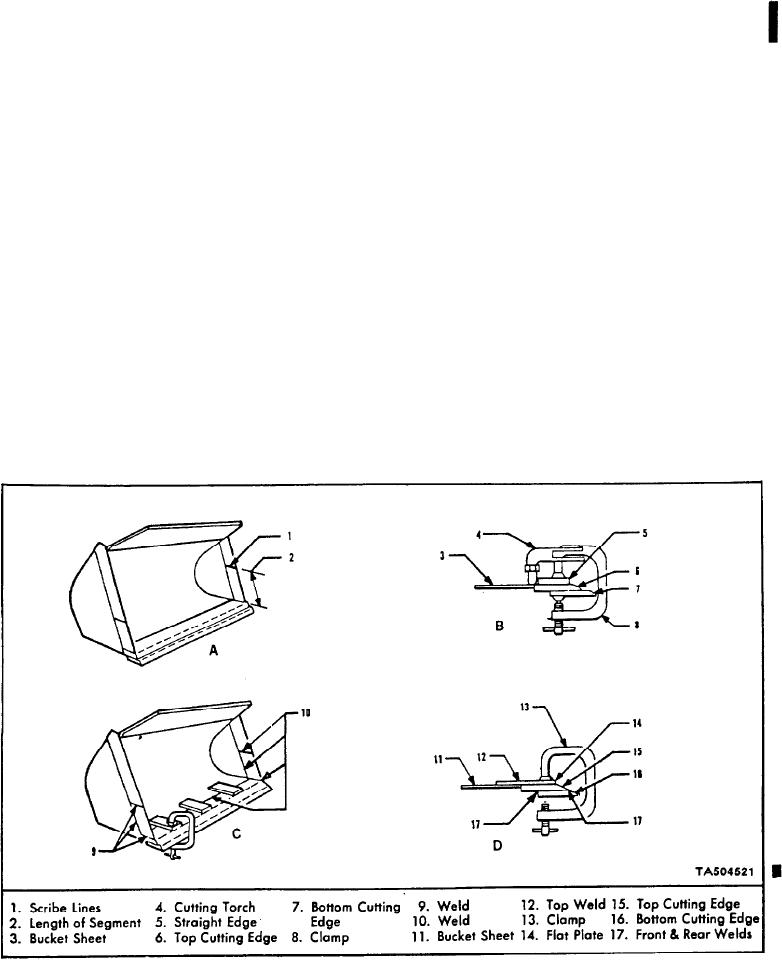

To replace bucket cutting edges, follow the pro-

ENGINE MAINTENANCE

cedure outlines in (a) and (b) below referring to

Figure 42 and Figure 42.1.

CHECK AND REPAIR BUCKET CUTTING EDGE

(a) Bottom Cutting Edge

CHECK BOOM TO BUCKET LINKAGE

1. Scarf out front and rear welds Item 17 securing

bottom cutting edge to top cutting edge as shown

INSPECT, TEST AND LUBRICATE

ELECTRICAL UNITS

in view "D". Grind rough edges smooth.

ADJUST STEERING GEAR

2. Align and clamp bottom cutting edge and tack

weld in place. See view "D".

INSPECT FRAME

3. Finish welding bottom cutting edge to top cut-

E n g i n e Maintenance: Refer to Operation and

ting edge. Front weld is a continuous 3/8 inch

M a i n t e n a n c e Manual of engine manufacturer for

fillet weld along entire edge. Rear weld is a 3/8

maintenance instructions of engine and accessor-

inch intermittent fillet weld consisting of a se-

ies.

ries of 3 inch welds equally spaced on 10 inch

centers.

Check and Repair Bucket Cutting Edge: The

b u c k e t should be periodically checked for badly

Note: Use a 3/16 diameter low hydrogen electrode

ripped, cracked, chipped or worn-out cutting edges

equivalent to AWS-E-10016.

(bottom and sides).

4. Grind front weld to present a smooth surface

for entry of material.

If at any time it becomes necessary to replace

the bucket cutting edge (bottom and or sides) re-

placement parts can be ordered separately. Refer

(b) Top, Bottom, and Side Cutting Edges

Fig. 42.

Repair Bucket Cutting Edge

[45-06-1]

Change 2